What is Powdered Activated Carbon and How is it Made

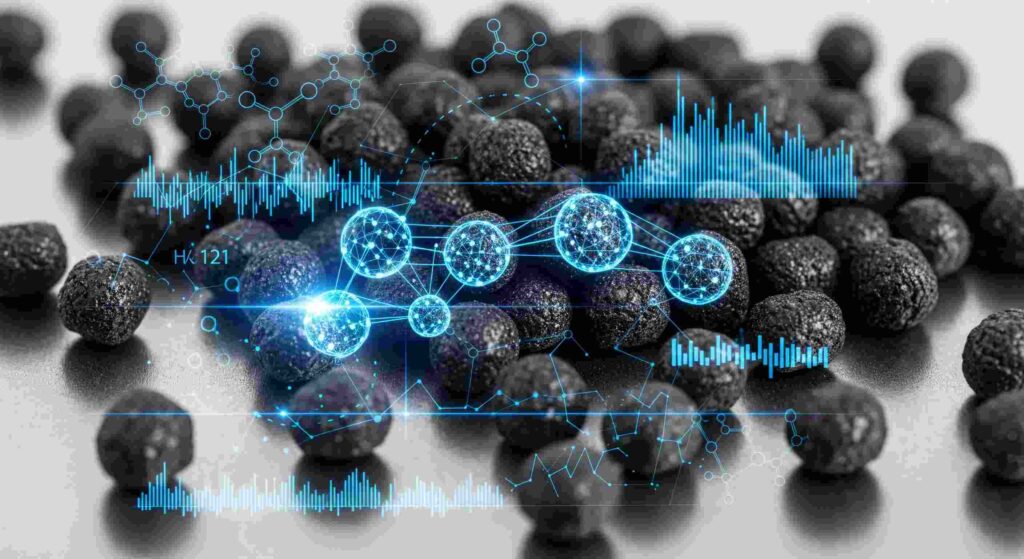

Image Source: unsplash You use powdered activated carbon when you need a material with tiny particles and a very large surface area. These small particles, usually less than 0.18 mm, help capture impurities quickly. The production process involves activating organic materials, which gives this carbon its unique adsorption ability. Type of Activated Carbon Particle Size […]

What is Powdered Activated Carbon and How is it Made Weiterlesen »