In industrial purification and treatment, powdered activated carbon (PAC) is a cornerstone technology. Its vast, porous internal structure makes it an unparalleled adsorbent for various contaminants. However, not all PACs are created equal. The difference between a successful application and a costly failure often lies within the fine print of a technical data sheet. For engineers, plant managers, and procurement specialists, the ability to decode PAC specifications is not just a technical skill—it is a critical component of strategic, cost-effective operations.

Selecting the correct PAC is a complex decision directly impacting process efficiency, final product quality, and the bottom line. Relying on surface-level information can lead to underperformance, system fouling, or unnecessary expenditure. A deep understanding of key metrics—from adsorption capacities like Iodine Number to physical characteristics like apparent Density—empowers professionals to move beyond generic solutions and select a carbon media precisely engineered for their unique challenge. This guide details the most essential PAC specifications, translating abstract numbers into real-world performance and tangible business value.

The Core Trio: Understanding Key Adsorption Metrics

The primary function of activated carbon is adsorption, a process dictated by its internal pore structure. Three key metrics provide a window into this structure, indicating the carbon’s affinity for different types of molecules.

Iodine Number: Gauging Micropore Volume for Small Contaminants

The Iodine Number is arguably the most fundamental parameter to characterize activated carbon. It is defined as the milligrams of iodine adsorbed by one gram of carbon under specific test conditions. Functionally, this value indicates the total micropore volume (pores <2 nanometers) within the carbon structure. A higher Iodine Number generally signifies greater activation and a larger surface area available for adsorption.

The Iodine Number is paramount for applications involving the removal of small, low-molecular-weight compounds. This is particularly relevant in potable water treatment, where the primary targets are often taste and odor compounds (T&O) like methyl isoborneol (MIB) and geosmin. These small organic molecules fit perfectly within the micropores, making a PAC with a high Iodine Number (typically >800 mg/g) the most effective and efficient choice.

Molasses Number: Measuring Macropore Capacity for Color Bodies

While micropores are vital, many industrial processes require the removal of much larger molecules. The Molasses Number is designed to measure the carbon’s capacity for these larger structures. It measures the PAC’s ability to adsorb color bodies from a standardized molasses solution, reflecting the volume of macropores (>50 nanometers) available.

A high Molasses Number is a critical specification in applications focused on decolorization. Industries such as sugar refining, chemical manufacturing, and textile wastewater treatment rely on PAC to remove large organic color molecules from their process streams. A PAC with a low Molasses Number would be ineffective in these scenarios, regardless of how high its Iodine Number might be, as the target molecules would be too large to access the smaller pores.

Tannin Number: Analyzing Mesopore Structure for Medium-Sized Organics

Bridging the gap between the micro- and macropores are the mesopores (2-50 nanometers). The Tannin Number is the metric used to evaluate this intermediate pore range. It measures the carbon’s capacity to adsorb tannins, medium-sized organic molecules commonly found in surface water sources.

This specification is crucial for treating natural organic matter (NOM) water. While not as large as the color bodies measured by the Molasses Number, tannins and other humic substances are significantly larger than T&O compounds. A PAC with a well-developed mesopore structure, indicated by a firm Tannin Number, will be more effective at removing these compounds, which can act as precursors to disinfection byproducts (DBPs) in chlorinated water systems.

Physical Properties That Dictate Performance and Handling

Beyond adsorption capacity, the physical characteristics of PAC have a profound impact on how it performs within a given system and how it must be handled and stored.

Particle Size Distribution: The Key to Reaction Speed and Filtration

Powdered activated carbon is defined by its small particle size. However, the specific distribution of those sizes is a critical performance lever. This is typically measured via sieve analysis, which determines the percentage of particles that pass through screens of varying mesh sizes.

Particle size directly influences the kinetics of adsorption. Smaller particles provide a shorter diffusion path to the internal pores, resulting in faster contaminant uptake. However, this must be balanced against the practicalities of the treatment system. Wonderful particles can be difficult to remove downstream, potentially leading to carryover and issues with filtration systems. Therefore, the optimal particle size distribution is application-specific, balancing the need for rapid kinetics with the demands of solid-liquid separation.

Apparent Density: Impact on Dosing, Storage, and Logistics

Users frequently search for information on powdered activated carbon density1, and for good reason. Apparent Density (also known as bulk density) is the mass of the carbon per unit of volume, including the space between particles. This metric has no direct bearing on adsorption capacity but is critically important for designing material handling infrastructure.

The apparent Density dictates the required volume for storage silos, the calibration of volumetric feeders and dosing systems, and the logistics of transportation. A low-density PAC will require a larger storage footprint and different feeder settings than a high-density alternative to deliver the same mass of carbon. Ignoring this specification can lead to significant operational challenges and inaccurate dosing.

Abrasion Resistance: Ensuring Durability and Minimizing Fines

Abrasion resistance measures the carbon’s ability to withstand degradation from friction and impact. A higher abrasion indicates a more complex, durable product less likely to break down during transport, handling, and slurry mixing.

This is important for two main reasons. First, product degradation represents a direct material loss, reducing the overall economic efficiency. Second, the breakdown of particles generates additional fine material, which can exacerbate downstream filtration problems and create dust hazards. A durable, low-dusting PAC is safer, cleaner, and more cost-effective.

Purity & Quality Control: The Specs That Ensure Safety and Reliability

For sensitive applications, the purity of the activated carbon is just as important as its performance. Several specifications provide insight into the quality and composition of the material.

Ash Content: Maximizing the Active Carbon You Pay For

Ash is the inorganic, non-carbon material that remains after the carbon has been completely combusted. It comprises minerals inherent in the original raw material (e.g., coal, wood, coconut shell). Meanwhile, inert ash contributes to the product’s weight without affecting adsorption. Therefore, a lower ash content signifies a higher-purity product with more active carbon per kilogram, representing superior value and performance.

Moisture Content: A Critical Factor in Purchasing and Handling

Activated carbon is typically sold by weight, and any moisture present is included in that weight. A specification for maximum moisture content ensures that the customer is not paying for excess water. Furthermore, high moisture levels can cause PAC to clump or bridge in storage silos and feeders, leading to significant handling and dosing problems. A tightly controlled moisture specification is a hallmark of a high-quality supplier.

pH and Water-Soluble Leachables: Protecting Your Process Integrity

The pH of the PAC slurry can influence the chemistry of the process in which it is being added. For most applications, a neutral pH is desired. Additionally, it’s crucial to ensure the carbon does not leach water-soluble materials, such as sulfates or chlorides, into the treated stream. For high-purity applications in the food, beverage, and pharmaceutical industries, specifications for low leachables are non-negotiable to prevent product contamination.

From Spec Sheet to Solution: Matching PAC Metrics to Your Application

The actual value of this data comes from synthesizing it to solve a specific problem. The ideal PAC specification profile is entirely dependent on the application.

Scenario 1: Municipal Water Treatment for Taste and Odor

A water utility is facing seasonal T&O complaints from its customers. The target contaminants are MIB and geosmin—small organic molecules. The critical PAC specification would be a very high Iodine Number to ensure maximum adsorption capacity for these micropollutants. Particle size would also be key, needing to be fine enough for rapid adsorption within the plant’s contact basin but not so fine as to overload the filters.

Scenario 2: Industrial Effluent Decolorization

A textile mill needs to remove residual dyes from its wastewater before discharge. The target contaminants are large, complex organic dye molecules. In this case, the Molasses Number would be the most critical metric, indicating a well-developed macropore structure capable of capturing these color bodies. Iodine Number would be a secondary consideration at best.

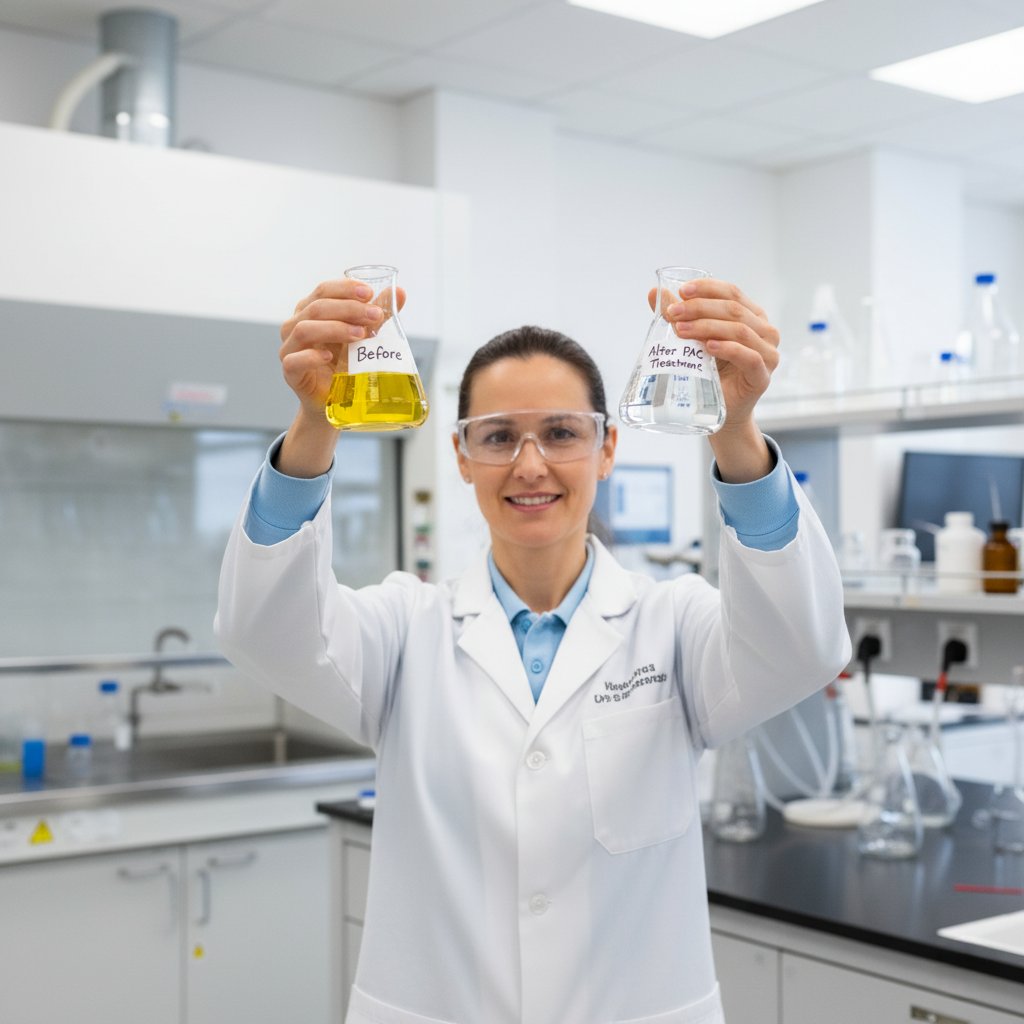

Application in Focus: Solving a Decolorization Challenge

A specialty chemical plant struggled to meet the color specification for a high-purity solvent. Their existing PAC failed to remove a persistent yellow tint, caused by large polymeric molecules. An analysis of their process revealed that while their current PAC had a respectable Iodine Number of 950 mg/g, its Molasses Number was only 120.

After a technical consultation, they switched to a wood-based PAC specifically engineered for decolorization. This new product had a slightly lower Iodine Number but a Molasses Number 210. The well-developed macropore structure of the new PAC was ideally suited to capture the large color bodies. Upon implementation, the plant achieved a 98% reduction in color, consistently meeting its final product specification and avoiding costly batch rejections. This demonstrates that selecting a PAC based on the correct primary specification is crucial for success.

A Strategic Approach to PAC Selection

A powdered activated carbon data sheet is more than a list of numbers; it is a roadmap to a targeted, effective, and efficient purification solution. Understanding the interplay between adsorption metrics, physical properties, and purity levels allows a discerning professional to see beyond marketing claims and evaluate a product’s technical merit.

Ultimately, the optimal solution involves a holistic analysis that balances these key performance indicators against your process’s specific operational and economic realities. The most effective path forward is a technical dialogue. By translating your unique challenge into the specifications language, you can ensure the PAC you procure is not just a commodity, but a strategic component engineered for your success. Suppose you are facing a complex purification challenge. In that case, the first step is to speak with an application engineer who can help you decode your needs and specify the perfect solution.