For a process engineer, selecting the right purification medium is a critical decision that extends far beyond material specifications. When it comes to activated carbon, the choice between powdered (PAC) and granular (GAC) forms is not merely about particle size; it’s a fundamental strategic choice that impacts capital expenditure (CapEx), operational expenditure (OpEx), system design, and long-term plant efficiency. While PAC and GAC are effective adsorbents, their physical forms dictate vastly different application methods, economic models, and operational protocols. This guide provides a detailed, engineering-focused comparison to help you move beyond a simple product-to-product evaluation and make a holistic, data-driven decision that aligns with your specific process requirements and financial objectives.

PAC vs. GAC: Key Differences at a Glance

Before diving into the technical nuances, a high-level overview can quickly frame the core distinctions between these two powerful purification tools. This table provides a scannable summary of the key differences that will inform a more detailed analysis.

| Feature | Powdered Activated Carbon (PAC) | Granular Activated Carbon (GAC) |

|---|---|---|

| Particle Size | Finely ground (<80 mesh, <0.177 mm) | Larger granules with a defined size range |

| Application Method | Dosed directly into liquid as a slurry in a batch process. | Used in a fixed-bed filter or column for continuous flow |

| Regeneration | No; designed for single-use and subsequent disposal | Yes; can be thermally reactivated multiple times |

| Initial Cost | Lower; approximately 2 to 3 times cheaper than GAC | Higher initial investment cost |

| Adsorption Speed | Rapid kinetics due to high external surface area | Slower kinetics as diffusion into granules takes time |

| Common Use Case | Intermittent or seasonal treatment; low dosage needs | Continuous, long-term purification in high-volume systems |

Application Methods: Batch Dosing vs. Continuous Flow Filtration

The physical form of the carbon directly dictates the engineering approach required for its implementation. Understanding these process differences is critical for assessing compatibility with existing infrastructure and planning for new system designs.

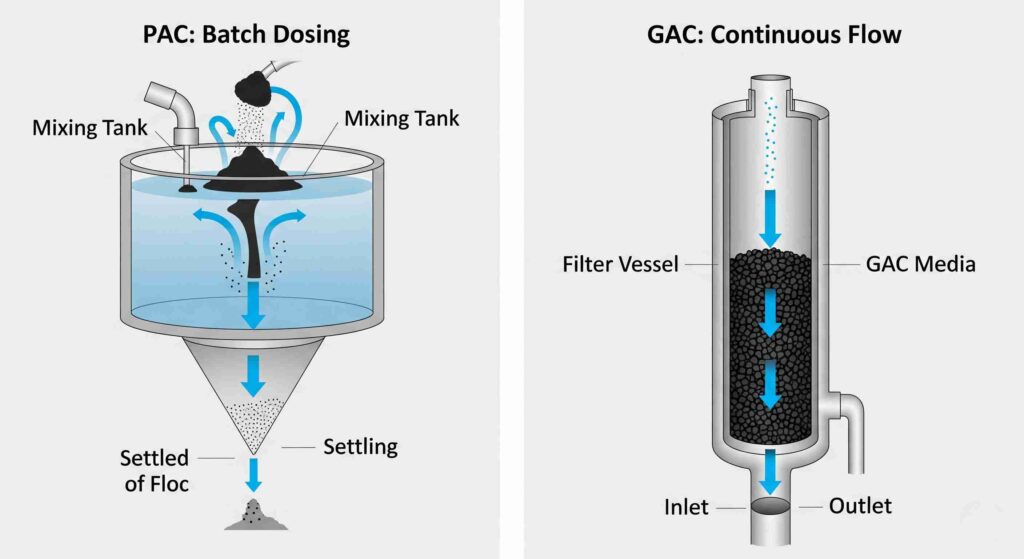

Powdered Activated Carbon (PAC): The Slurry & Settle Method

PAC is utilized in a batch or semi-batch process. It is typically mixed with water to form a slurry, which is then dosed directly into a contact tank or an existing process stream, such as an aeration basin in a wastewater plant. The fine particles provide a vast surface area, allowing for rapid adsorption of contaminants. However, this method introduces a critical downstream requirement: the PAC must be separated from the treated liquid. This is usually accomplished through sedimentation, followed by a polishing filtration stage (such as a sand or cloth filter) to capture any fine carbon particles that do not settle, ensuring the final effluent is carbon-free.

Granular Activated Carbon (GAC): The Fixed-Bed Adsorber

GAC is used in a continuous flow system. The granules are loaded into large vessels, columns, or filters to create a fixed bed. Contaminated liquid or gas is passed through this bed, and purification occurs as the contaminants adsorb onto the carbon granules. This method provides consistent, long-term treatment and functions as both adsorbents and filters. The system operates continuously until the GAC bed becomes saturated with contaminants. At this point, it must be taken offline for carbon replacement or regeneration.

The Economic Equation: Analyzing Total Cost of Ownership (TCO)

A procurement decision based solely on the upfront price per ton is incomplete. A thorough Total Cost of Ownership (TCO) analysis reveals a more accurate financial picture, empowering you to build a robust business case for either option.

- Initial Purchase Price (CapEx): PAC is significantly cheaper on a per-ton basis, often two to three times less expensive than GAC. This makes it an attractive option for projects with stringent upfront capital constraints or applications where carbon is needed only for short-term, emergency interventions.

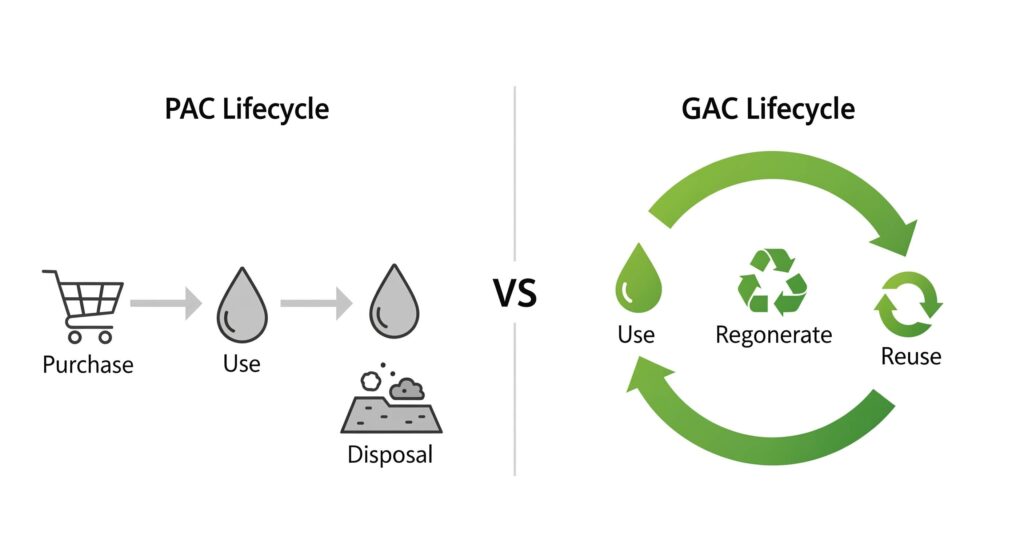

- Regeneration vs. Disposal (OpEx): This is the most critical factor in the long-term economic comparison. GAC can be removed from its vessel and thermally reactivated off-site, restoring its adsorptive capacity for reuse. This regeneration cycle dramatically reduces long-term material costs. In contrast, PAC is a single-use product; once spent, it cannot be reactivated and must be disposed of, representing a recurring operational cost.

- Dosage Flexibility & Cost Control: PAC offers a distinct advantage in treating intermittent or seasonal contamination, such as taste and odor events in municipal water. The dosage can be precisely adjusted or stopped altogether based on fluctuating contaminant levels, preventing material waste and controlling costs. GAC systems, being continuous, are less suited for such variability.

Operational & Environmental Considerations

Beyond the economics, each carbon type’s day-to-day operational impact and environmental footprint are key considerations for plant managers and safety officers.

For PAC:

Using PAC introduces several operational burdens. In wastewater treatment, its addition proportionally increases the volume of sludge produced, which requires management and disposal. The delicate nature of the powder necessitates robust downstream filtration to prevent carbon fines from contaminating the final effluent. Furthermore, as a fine combustible dust, PAC poses a potential dust explosion hazard and requires specific handling and storage protocols to ensure plant safety.

For GAC:

The primary operational considerations for GAC are carbon exchange and regeneration logistics. This involves coordinating with a service provider to remove the spent carbon and replace it with fresh or reactivated material. From an environmental perspective, GAC holds a significant advantage. The ability to regenerate and reuse the carbon results in a much lower greenhouse gas footprint than the production and disposal of single-use PAC, aligning with corporate sustainability goals.

Which is Right for Your Application? A Decision Framework

Synthesizing the technical, economic, and operational factors, this framework provides a clear guide to help you make a final, justifiable recommendation.

- Choose PAC if your process involves:

- Intermittent or seasonal contamination (e.g., seasonal taste/odor events).

- Low, infrequent dosage requirements.

- An existing clarification or filtration system that can handle carbon fines.

- Strict upfront capital budget (CapEx) limitations.

- Choose GAC if your process involves:

- Continuous, high-volume treatment needs.

- Long-term, predictable contaminant loads.

- A focus on minimizing long-term operating costs (OpEx) and labor.

- Sustainability goals and a desire to reduce waste and carbon footprint.

People Also Ask (FAQ Section)

1. Can you regenerate powdered activated carbon (PAC)?

No. PAC is designed for single-use applications and is typically disposed of after use. Only granular activated carbon (GAC) has the physical properties to be thermally regenerated and reused.

2. Is PAC or GAC better for removing taste and odor from drinking water?

Both are highly effective. The choice depends on the nature of the problem. PAC is often dosed into reservoirs on a seasonal or as-needed basis to handle specific events. At the same time, GAC is used in large filter beds for continuous, year-round treatment.

3. What are the main disadvantages of using PAC?

The primary disadvantages are that it cannot be reactivated, it increases the volume of sludge that must be handled and disposed of in wastewater applications, and its fine particles can be difficult to handle and require downstream filtration to contain.

4. Why is GAC more expensive than PAC initially?

The manufacturing and sizing process for creating durable granules is more complex than for producing a fine powder, leading to a higher upfront material cost. However, this initial investment is often offset over the product’s lifecycle by its reusability through regeneration.

Suggested Call to Action (CTA):

Have a complex application or need help selecting the right carbon? Contact our engineering experts for a no-obligation consultation or to request a product sample.