If you look at a handful of activated carbon, it all looks the same: a black, dusty, granular material. But if you were to zoom in with an electron microscope, you would see vastly different landscapes.

Choosing the right activated carbon isn’t just about buying “the black stuff.” The raw material—whether it’s coconut shell, coal, or wood—determines the internal pore structure of the carbon. This structure dictates whether your filter will successfully trap invisible toxic gases or fail completely.

In this guide, we will break down the three primary sources of activated carbon, explain the science of pore sizes, and help you decide which material is right for your water or air filtration needs.

The Science of Structure: Why Source Matters

Before comparing materials, we need to understand how activated carbon works. It does not “absorb” contaminants like a sponge soaking up water. Instead, it works through adsorption.

Adsorption is a surface phenomenon. Think of activated carbon as a molecular magnet. When fluid (water) or gas (air) passes over the carbon, impurities stick (adhere) to the surface of the carbon’s internal pores.

The “Parking Lot” Analogy

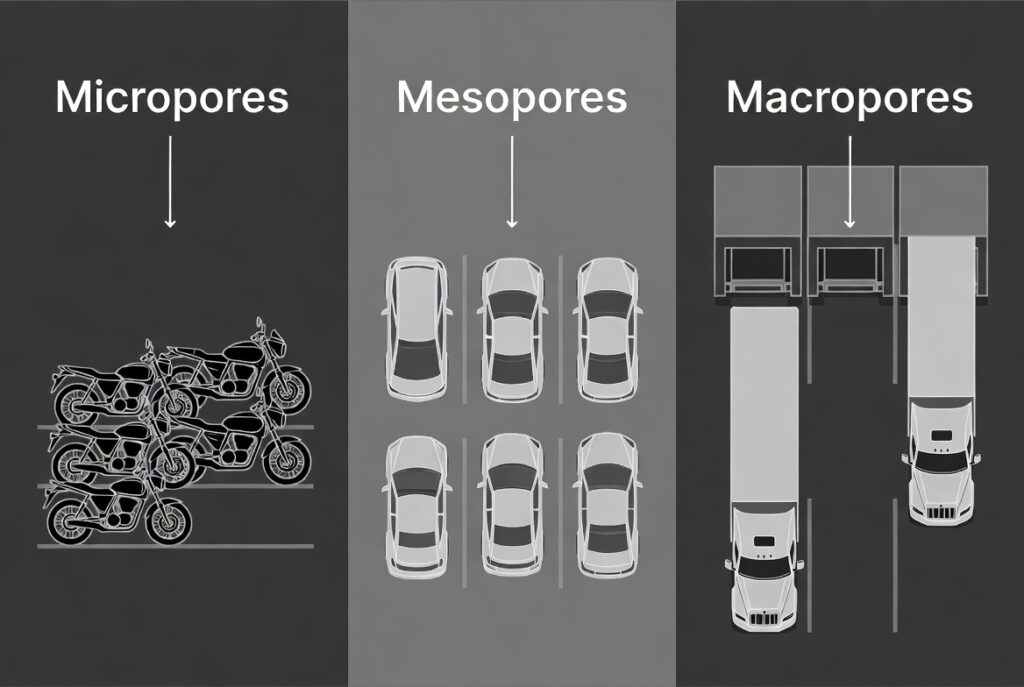

To understand why the raw material matters, imagine the internal structure of activated carbon as a massive parking lot.

- Micropores (Small Spots): These are tiny parking spots, perfect for motorcycles or compact cars. In filtration, these trap small molecules like volatile organic compounds (VOCs) and chlorine.

- Mesopores (Medium Spots): These are standard spots for sedans and SUVs. They trap medium-sized molecules.

- Macropores (Large Spots): These are giant loading docks for semi-trucks. They trap large molecules, such as heavy proteins or color pigments.

The raw material (the source) determines the ratio of these parking spots. If you try to park a semi-truck (large color molecule) in a motorcycle spot (micropore), it won’t fit. The filter will fail.

Visual Note: Imagine a cross-section of a carbon granule. Coconut shell carbon looks like a dense sponge with tiny pinholes (micropores). Wood carbon looks like a cavernous Swiss cheese (macropores).

Coconut Shell Activated Carbon: The Micropore King

Coconut shell activated carbon is currently the most popular choice for home water filters and air purification systems. It is produced by heating coconut shells to high temperatures in the presence of steam.

Characteristics

- Dominant Pore Size: Micropores (Small). Roughly 85-90% of its surface area consists of these tiny pores.

- Hardness: Very hard and durable. It produces very little dust compared to other types.

- Contenu en cendres : Low. This means fewer impurities leach back into the water.

Best Applications

Because it is packed with “motorcycle spots,” coconut shell carbon is the gold standard for trapping small, light molecules.

- Drinking Water Polishing: It is excellent at removing chlorine, bad tastes, and odors (CTO). The small pores tightly bind the small chlorine molecules.

- Air Purification: It is highly effective against Volatile Organic Compounds (VOCs) like benzene, toluene, and common household odors.

- Breathable Masks: Due to its high density and efficiency, it is often used in gas mask filters and respirators.

The Eco-Friendly Bonus: Coconut shells are a renewable resource—a byproduct of the food industry that would otherwise be waste.

Coal-Based Activated Carbon: The Industrial Workhorse

Coal-based activated carbon usually comes from bituminous coal or anthracite. It is the heavy lifter of the industrial world. Unlike the uniform structure of coconut, coal is formed over millions of years, resulting in a more complex internal structure.

Characteristics

- Dominant Pore Size: A mix of Micropores and Mesopores.

- Density: High density, similar to coconut, but generally softer.

- Contenu en cendres : Higher than coconut or wood (requires acid washing for high-purity applications).

Best Applications

Coal-based carbon casts a “wider net.” Because it has both small and medium parking spots, it can handle a chaotic mix of contaminants.

- Wastewater Treatment: Industrial runoff often contains a mix of chemicals—some small, some medium. Coal carbon handles this variety better than coconut.

- Dye Removal: It can trap some larger color molecules that coconut carbon would miss.

- Aquariums: Many aquarium filters use bituminous coal carbon because it effectively removes organic waste without clogging too quickly.

Wood-Based Activated Carbon: The Macropore Giant

Wood-based activated carbon is distinctively different. It is physically softer and creates a vastly more open internal structure. It is often sold as Charbon actif en poudre (PAC) because granules of wood carbon can crush easily under pressure.

Characteristics

- Dominant Pore Size: Macropores and Mesopores (Large to Medium).

- Texture: Soft, lightweight, and dusty.

- Adsorption Speed: Extremely fast. The large “highways” allow liquid to flow in and out of the pores quickly.

Best Applications

You need wood carbon when you are trying to park “semi-trucks.”

- Decolorization: If you need to remove dark colors from cane sugar syrup, juices, or liquor, wood carbon is the best choice. The large color molecules fit easily into the macropores.

- Medical & Pharmaceutical: In emergency rooms, wood-based activated carbon is often used to treat poisoning. Its large pores and rapid adsorption rate allow it to soak up toxins in the stomach quickly before they enter the bloodstream.

Medical Disclaimer: Never attempt to use activated carbon for poisoning or overdose treatment at home without direct instruction from medical professionals or poison control. Dosage and timing are critical.

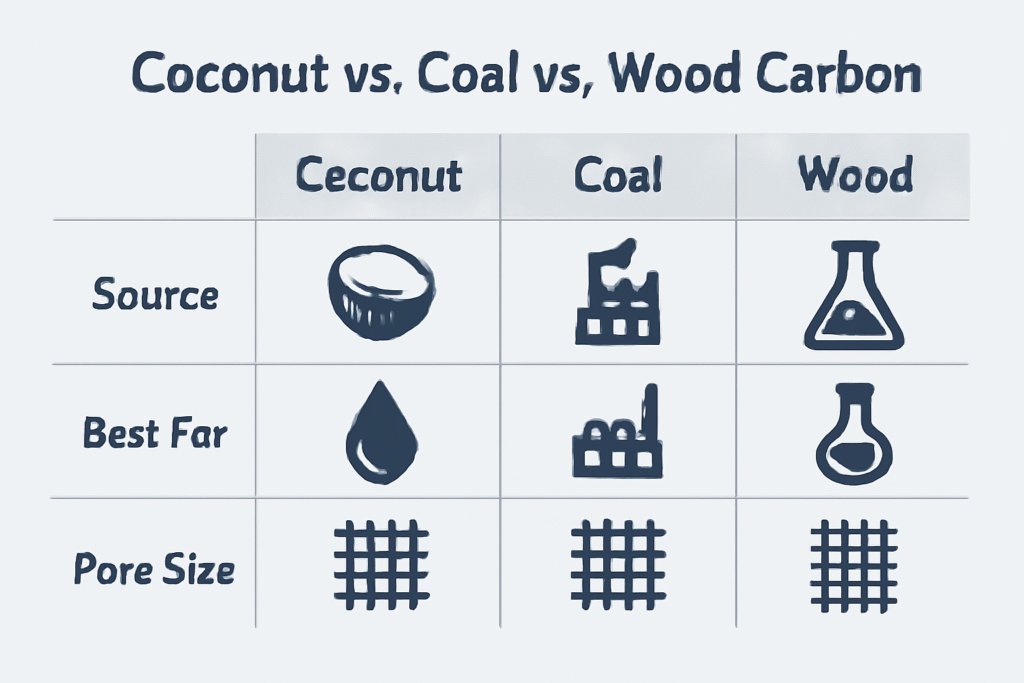

Cheat Sheet: Comparing Carbon Sources

If you are skimming, here is the breakdown of how to match the source to the problem.

| Feature | Coconut Shell | Charbon bitumineux | Wood-Based |

|---|---|---|---|

| Primary Pore Type | Micropores (Tiny) | Mix (Micro/Meso) | Macropores (Large) |

| Dureté | High (Low dust) | Medium | Low (High dust) |

| Best For | Water taste, Chlorine, VOCs, Air filters | Wastewater, General organics | Decolorizing, heavy liquids |

| Sustainability | High (Renewable) | Low (Mined) | High (Renewable) |

Summary: The best activated carbon source depends on the target contaminant. Coconut shell carbon is superior for small molecules like VOCs and chlorine due to its microporous structure. Coal-based carbon offers a versatile pore mix for general wastewater treatment. Wood-based carbon features large macropores, making it ideal for decolorization and liquid purification.

Sustainability and Safety Considerations

While activated carbon is a powerful tool, it comes with handling risks that are often overlooked in general guides.

1. The Oxygen Warning

Wet activated carbon removes oxygen from the air. If you are a facility manager working with large tanks of activated carbon, simply wetting the carbon can cause it to strip oxygen from the surrounding environment. Entering a confined space containing wet carbon is a suffocation hazard. Always ensure proper ventilation and follow OSHA confined space protocols.

2. Flammability and Dust

Dry activated carbon dust—especially from wood or coal sources—is combustible. In industrial settings, dust collection systems are required to prevent explosion risks. For home users, this mostly means you should rinse your carbon filter (if the manual allows) to remove the black dust before use, so it doesn’t clog your equipment or end up in your drinking water.

Matching the Source to the Solution

Activated carbon is not a single product; it is a family of materials.

- If you are filtering tap water or air in your home, look for Coconut Shell carbon. It’s cleaner, harder, and traps the tiny contaminants you care about.

- If you are treating industrial wastewater, Coal-based carbon is likely your versatile workhorse.

- If you need to remove color from a liquid, Wood-based carbon is the specialist you need.

Next Steps: Check your current filter specifications. Does it list the raw material? If you are struggling with a specific filtration issue—like a persistent odor or color—you may simply be using the wrong carbon source for the job.

Want to dive deeper into filtration forms? Read our guide on [GAC vs. Carbon Block] to understand how physical shapes impact performance.

Foire aux questions (FAQ)

1. Is “activated charcoal” the same as “activated carbon”? Yes. The terms are generally used interchangeably. “Charcoal” is often used in consumer or medical contexts (like toothpaste or supplements), while “Carbon” is the preferred technical term for industrial and filtration applications. They are the same material.

2. Can I make activated carbon at home? Technically, yes, but practically, no. True activation requires heating carbon-rich material to extreme temperatures (over 800°C) in a controlled environment with steam or chemicals to blast open the pores. Simply burning wood in your backyard creates charcoal, which has very low surface area compared to charbon actif and will not filter effectively.

3. Which carbon is best for removing chloramine? While standard coconut shell carbon removes chlorine well, chloramine (a mix of chlorine and ammonia often used in city water) is harder to remove. You generally need a “catalytic” carbon—usually a specially modified coconut shell carbon—to break down chloramine effectively.

4. How do I know when my activated carbon is used up? Activated carbon does not change color when it is full. The only way to know is when “breakthrough” occurs—meaning the contaminant starts passing through the filter. For water filters, this usually manifests as the return of a bad taste or smell (like chlorine). It is best to stick to the manufacturer’s recommended replacement schedule (e.g., every 6 months).