Why the Source Material is the Blueprint for Performance

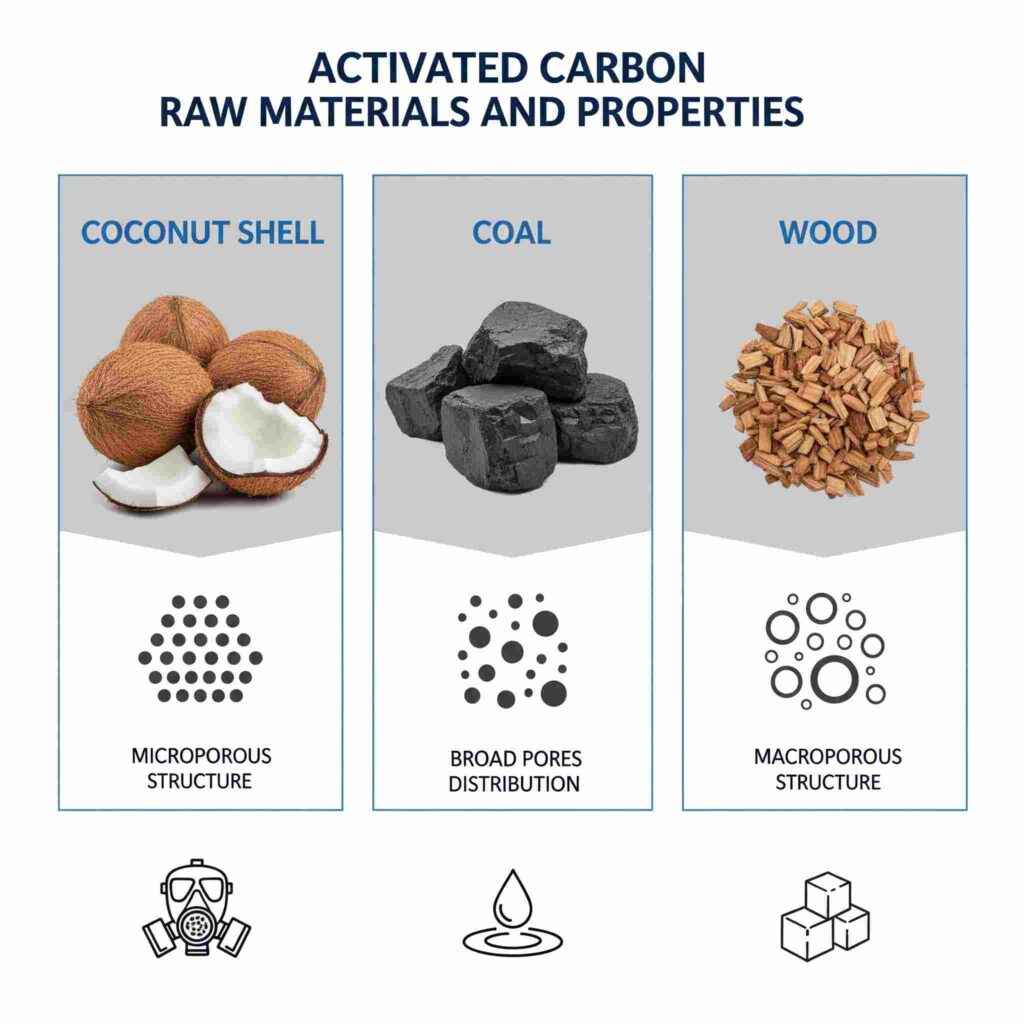

To a process engineer, selecting the right activated carbon is a decision with significant consequences for efficiency, cost, and final product quality. While factors like particle size and activation method are essential, the raw material is the most critical variable. Not all activated carbon is created equal, and its performance is fundamentally predetermined by its origin. The source material—whether it’s coconut shell, coal, or wood—acts as the blueprint for the carbon’s internal pore structure. This microscopic architecture dictates which contaminants the carbon can adsorb most effectively, how quickly it works, and which applications it is best suited for. Understanding the distinct characteristics imparted by each raw material is the first step in optimizing any purification process.

The “Big Three” Carbon Sources: A Technical Deep Dive

Most industrial activated carbon originates from one of three primary sources. Each material yields a final product with a unique profile of strengths, weaknesses, and economic considerations that every engineer and procurement manager should understand.

Coconut Shell-Based Activated Carbon: The Microporous Workhorse

Activated carbon derived from coconut shells is renowned for its highly microporous structure. It possesses a high volume of tiny pores. This characteristic makes it exceptionally effective at adsorbing small organic molecules and contaminants from gas and liquid phases.

- Ideal Applications: Its pore structure makes it a top performer in applications requiring the removal of trace contaminants. This includes gas-phase purification, treating municipal drinking water to remove disinfection byproducts, and specialized industrial processes like gold recovery.

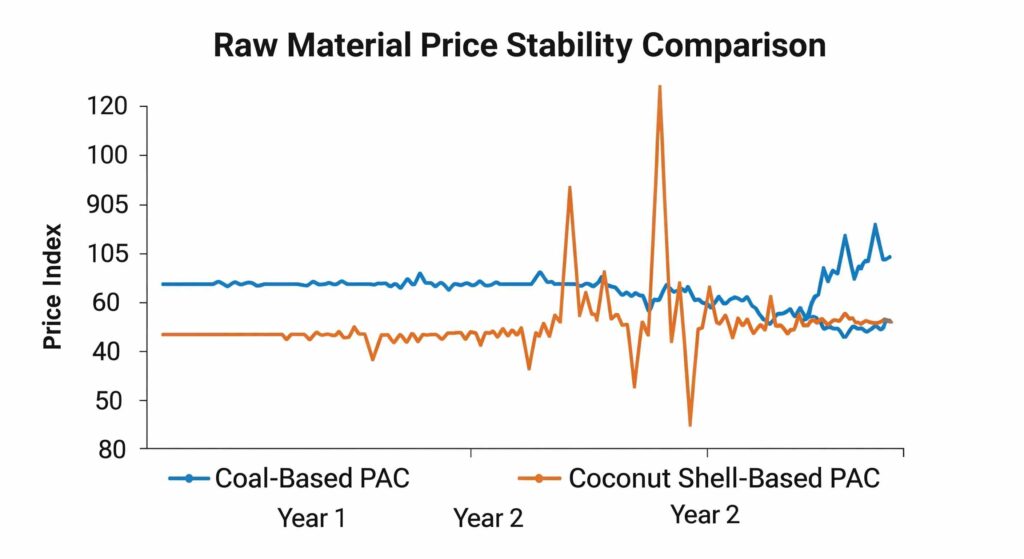

- Procurement Considerations: Coconut shell-based carbon often commands a 25-40% price premium over coal-based alternatives due to its superior hardness and adsorption properties. However, as an agricultural product, its supply chain is subject to variability, leading to annual potential price fluctuations of 12-15%.

Coal-Based Activated Carbon: The Versatile and Stable Option

Coal-based activated carbon is a versatile, general-purpose adsorbent characterized by a broader distribution of pore sizes, including mesopores and macropores. This balanced structure effectively absorbs a wide range of different-sized molecules.

- Ideal Applications: It is a reliable choice for general water and wastewater treatment and industrial decolorization, and it is particularly effective in specialized applications like removing mercury from the flue gas of coal-fired power plants.

- Procurement Considerations: Compared to agricultural sources, the supply chain for coal is generally more stable. This results in more predictable and consistent pricing, making it an attractive option for large-scale industrial users who require long-term budget stability.

Wood-Based Activated Carbon: The Decolorization Specialist

Wood-based activated carbon is distinguished by its predominantly macroporous structure. Its larger pores are ideally suited for adsorbing large, complex organic molecules, particularly the color bodies of food and chemical products.

- Ideal Applications: This material excels in high-purity applications where decolorization is the primary goal. It is the product of choice for purifying sweeteners, glycerin, and edible oils and removing impurities from active pharmaceutical ingredients (APIs).

- Procurement Considerations: Procurement for wood-based carbon is often driven by the need for specific certifications. Many grades are available that meet the stringent standards of the Food Chemical Codex (FCC) and are certified as Kosher and Halal, making them suitable for food, beverage, and pharmaceutical manufacturing.

Raw Material Comparison: A Side-by-Side Analysis for Engineers

For a quick evaluation, this table summarizes the key decision-making criteria for each primary raw material, allowing for a rapid comparison based on your specific process needs.

| Feature | Coconut Shell-Based | Coal-Based | Wood-Based |

|---|---|---|---|

| Primary Pore Structure | Microporous | Broad Distribution | Macroporous |

| Best For Adsorbing | Small organic molecules, gases | General purpose, various organics | Large color bodies, complex molecules |

| Key Applications | Air purification, drinking water, wastewater, mercury removal, food & pharma decolorization | General water treatment, industrial decolorization, mercury removal | Food & pharmaceutical decolorization, glycerin and sweeteners purification |

| Price Volatility | Higher | Lower / More Stable | Varies by source |

How to Select the Right Raw Material for Your Application

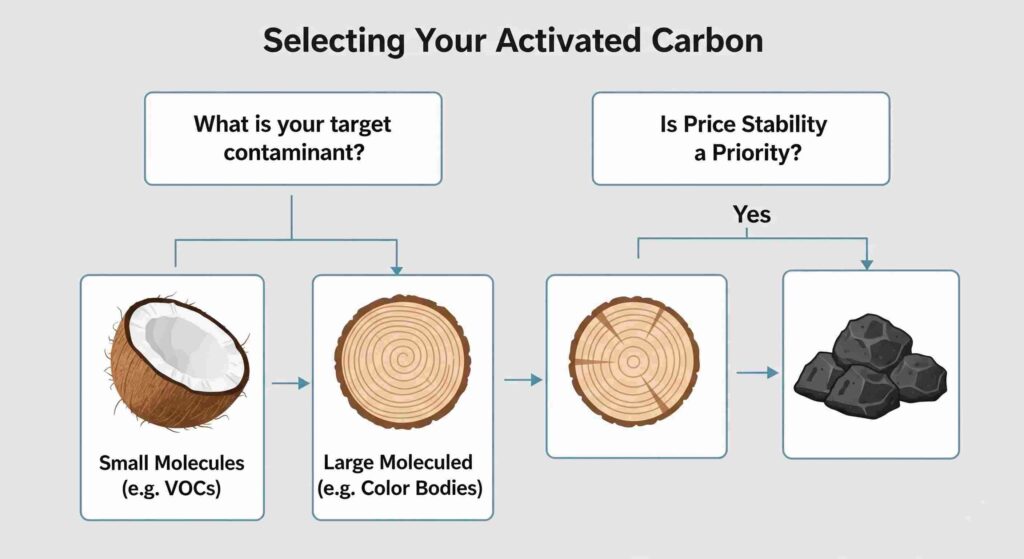

Translating this technical data into a confident decision requires a structured approach. Follow this four-step framework to match your purification challenge to the optimal activated carbon raw material.

- Step 1: Identify Your Target Contaminant: The most crucial factor is the molecule size you must remove. Are you targeting small, dissolved volatile organic compounds (VOCs), which points toward a microporous coconut shell-based carbon? Or are you removing large, complex color molecules from a syrup, which indicates a macroporous wood-based carbon is the better choice?

- Step 2: Define Your Process: Consider the phase of your application. While all three materials are used in liquid-phase processes, coconut shell-based carbon’s high hardness and microporosity often make it a preferred choice for gas-phase applications.

- Step 3: Consider Your Budget & Supply Chain Needs: Evaluate your financial and logistical priorities. Suppose your process requires absolute price stability for long-term contracts. In that case, the more stable supply chain of coal-based carbon is a significant advantage. Suppose maximum performance for a specific contaminant is the primary driver. The coconut shell’s premium cost and potential price swings may be justified in this case.

- Step 4: Verify Certification Requirements: Confirm your industry’s regulatory and quality standards. The carbon must be certified to NSF/ANSI 61 standards if your application involves drinking water. For food or pharmaceutical use, you will likely require a product that meets Food Chemical Codex standards and may need Kosher or Halal certification.

People Also Ask (FAQ Section)

1. Does the manufacturing process change for different raw materials?

Yes. While the fundamental process of pyrolysis and steam activation remains similar, manufacturers adjust key parameters like temperature, steam concentration, and activation time based on the specific raw material to engineer the desired final pore structure.

2. Is one raw material more environmentally friendly than another?

Materials like coconut shell and wood are considered renewable resources, which can be a factor in sustainability assessments. The manufacturing method also plays a role; steam activation is cleaner than chemical activation. For granular activated carbon (GAC), the ability to be thermally regenerated offers a significant sustainability benefit by reducing waste and greenhouse gas emissions compared to single-use powdered activated carbon (PAC).

3. Why is coconut shell activated carbon more expensive?

Coconut shell-based carbon typically commands a price premium for its superior physical properties (like hardness) and its highly microporous structure, which delivers excellent performance in high-value applications. The supply and demand dynamics of an agricultural commodity also influence its price.

4. Can I use any activated carbon for drinking water?

No. You must use an activated carbon certified to NSF/ANSI 61 standards for any potable water application. This certification ensures the product is safe for contact with drinking water and will not leach any harmful substances.