For process engineers and procurement directors, selecting an activated carbon system is a significant financial and operational decision. On the surface, powdered activated carbon (PAC) is often the more economical choice due to its lower upfront purchase price. However, this initial price tag represents only a fraction of the lifetime cost. A financially sound decision requires a deeper analysis using the Total Cost of Ownership (TCO) framework. TCO provides a comprehensive view of the initial purchase and all recurring operational costs over the system’s lifecycle. This guide deconstructs the TCO for PAC and granular activated carbon (GAC) systems. It provides a practical tool to help you build a data-driven business case for the most cost-effective solution for your specific application.

Deconstructing TCO: Capital vs. Operational Expenditures (CapEx vs. OpEx)

To accurately compare PAC and GAC, we must break down the total cost of ownership into two fundamental components: capital and operational expenditures.

Capital Expenditures (CapEx)

These are the one-time, upfront investments required to design and install the system. This includes the cost of the initial carbon fill and all necessary process equipment, such as tanks, pumps, and vessels.

Operational Expenditures (OpEx)

These are the recurring, ongoing costs required to run and maintain the system year after year. This includes critical expenses like carbon replacement, disposal fees, maintenance, and labor.

Understanding the balance between these two categories is the key to revealing the actual long-term cost of each technology.

Analyzing the Upfront Investment: A CapEx Comparison

The initial capital investment is where PAC often presents its most compelling, though potentially misleading, advantage.

Initial Carbon Purchase Price

The most straightforward component of CapEx is the material cost. On a per-ton basis, powdered activated carbon is approximately two to three times cheaper than granular activated carbon. This lower initial material cost can significantly influence projects with extremely tight upfront capital constraints.

System & Infrastructure Costs

The equipment required for each system also contributes to the initial CapEx. A PAC system requires a slurry tank and a dosing unit, which can represent a significant investment for an automated system. Furthermore, because PAC increases sludge volume, it may necessitate capital investment in an upgraded sludge handling or dewatering system. In contrast, a GAC system requires a larger capital investment in fixed-bed adsorber vessels designed to hold the carbon media.

The Long-Term View: A Deep Dive into Operational Expenditures (OpEx)

While PAC may have a lower initial CapEx, the long-term operational expenditures often tell a different financial story. This is where the actual cost of an activated carbon system is revealed.

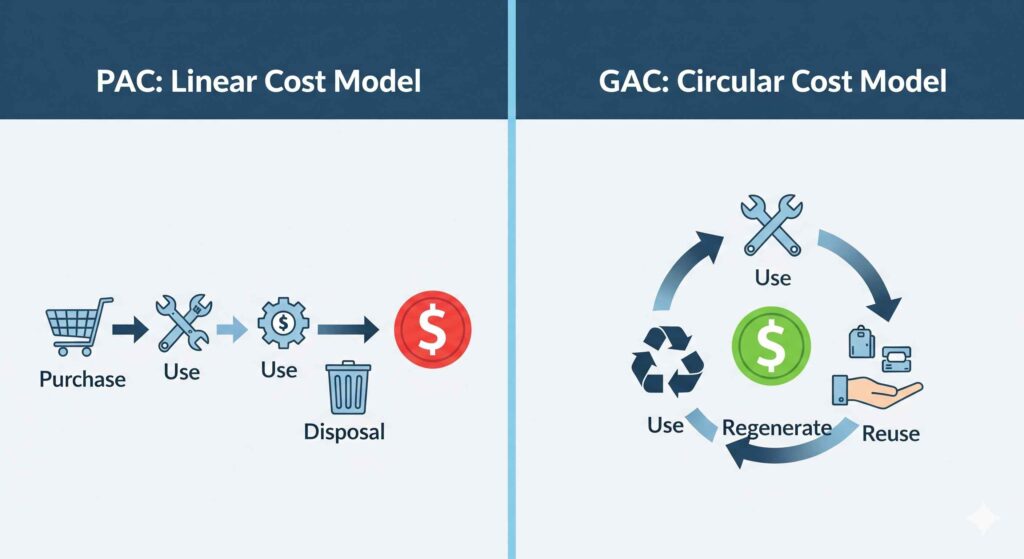

The Regeneration vs. Disposal Cycle

This is the fundamental OpEx difference between the two technologies.

- GAC: Granular activated carbon is designed for reuse. Once saturated, it can be removed and sent to a specialized facility for thermal regeneration. This process restores its adsorptive capacity. The recurring OpEx includes the service fee for this regeneration and the cost of replacing the 5-10% carbon lost during each cycle.

- PAC: Powdered activated carbon is a single-use product. Due to its fine particle size, it cannot be economically regenerated. This means that 100% of the carbon must be continuously repurchased and disposed of, creating a significant and perpetual line item in the operational budget.

Sludge Management & Disposal Fees

A critical “hidden cost” associated with PAC, particularly in wastewater treatment, is the impact on downstream processes. The addition of PAC proportionally increases the volume of sludge produced. This creates a significant operational burden and recurring cost for sludge handling, dewatering, and final disposal. Furthermore, suppose the spent carbon has adsorbed hazardous materials. In that case, it requires special handling and disposal at a licensed facility, adding another layer of cost and complexity.

Maintenance & Labor

Operational costs also include the labor and parts needed for system upkeep. PAC slurries can be abrasive, potentially leading to increased maintenance requirements for pumps, pipes, and dosing equipment. GAC systems, while generally lower in maintenance, require labor to coordinate the logistics of carbon exchange and off-site regeneration services.

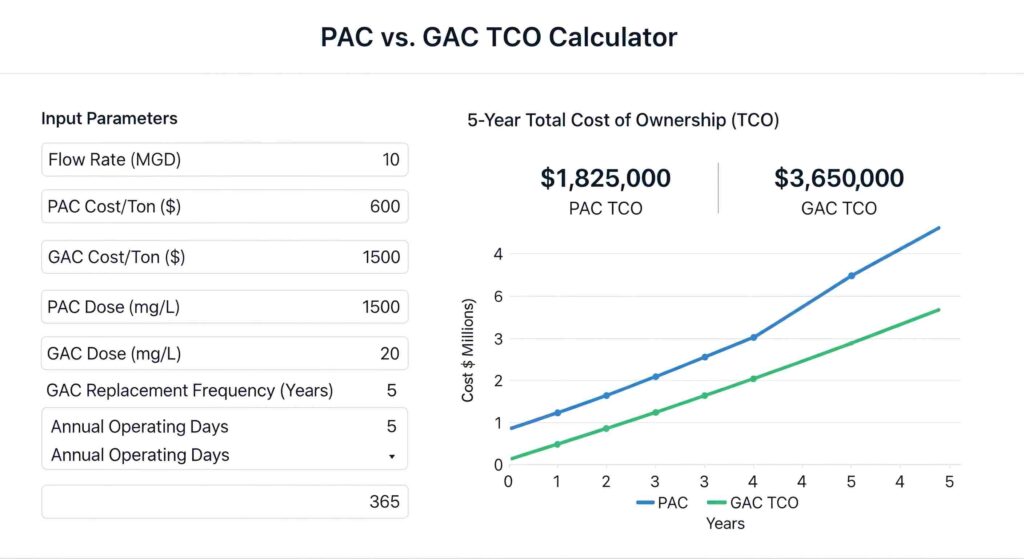

The Interactive PAC vs. GAC TCO Calculator

Stop guessing and start calculating. The theoretical differences in CapEx and OpEx become clear when applied to your specific process variables. Use our free, interactive TCO Calculator below to build a robust business case and see the actual 5-year cost of each system.

Enter your project variables to see your customized TCO projection:

- Process Flow Rate

- Annual Operating Hours

- Estimated Carbon Consumption Rate

- Analysis Period (1, 3, or 5 years)

- Cost Inputs (per ton): PAC Purchase Price, GAC Purchase Price, GAC Regeneration Fee, Spent PAC Disposal Fee

- System Inputs: GAC Regeneration Loss Rate (%), CapEx for PAC System, CapEx for GAC System

Outputs:

- A side-by-side comparison of Total CapEx, Total OpEx, and the cumulative Total Cost of Ownership over your selected period.

- A dynamic line graph that visually tracks the cumulative cost of each system over time, clearly identifying the financial break-even point where the lower OpEx of a GAC system begins to deliver significant savings.

People Also Ask (FAQ Section)

1. Why isn’t powdered activated carbon (PAC) regenerated?

Typically, PAC is not regenerated because its fine particle size makes it technically difficult and uneconomical to handle in the high-temperature thermal kilns used for regeneration. It is engineered as a single-use product that is disposed of after use.

2. What is PAC’s most significant “hidden cost”?

In wastewater applications, increased sludge production is one of the most significant hidden costs. This creates additional downstream operational expenses for sludge handling, dewatering, and disposal that are not reflected in the initial price per ton of carbon.

3. How much carbon is lost during GAC regeneration?

During the thermal regeneration process, it is common to have carbon losses between 5% and 10% due to mechanical handling and the burn-off of some carbon along with the adsorbed contaminants. After each cycle, this lost volume must be replaced with new “makeup” carbon.

4. Can I reduce my carbon consumption to lower my OpEx?

Yes. Optimizing your dosage based on contaminant levels is the most direct way. Additionally, selecting a higher-activity carbon (e.g., a higher iodine value), while potentially having a 30% higher initial cost, can reduce overall consumption by up to 40%, leading to a significant long-term reduction in OpEx.

Suggested Call to Action (CTA):

Your TCO calculation is the first step. For a detailed analysis of your application and to discuss system optimization, contact our engineering experts for a complimentary consultation.