Introduction: The Microscopic Sponge with Miles of Surface Area

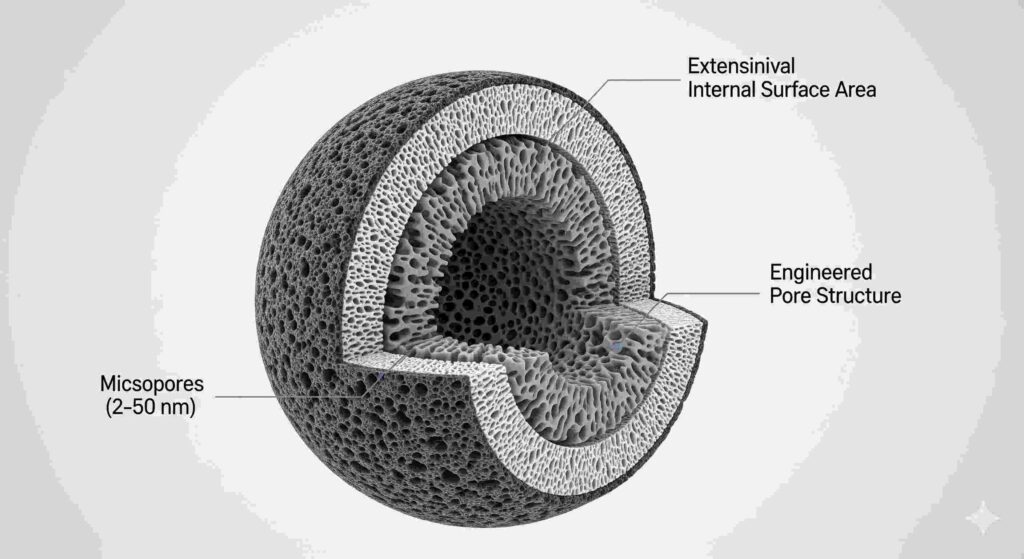

To the naked eye, powdered activated carbon (PAC) is a simple, fine black powder. However, on a microscopic level, it is a highly engineered material with a complex internal structure. Think of each particle not as a solid speck, but as a microscopic sponge, riddled with an intricate network of pores and channels. This structure gives PAC a huge internal surface area; a single gram can have a surface area of over 400 square meters. This vast, hidden surface is the key to its power. The remarkable ability of powdered activated carbon to purify liquids and gases stems from a powerful surface phenomenon known as adsorption, which allows it to capture and hold a wide array of contaminants.

Adsorption vs. Absorption: A Critical Distinction

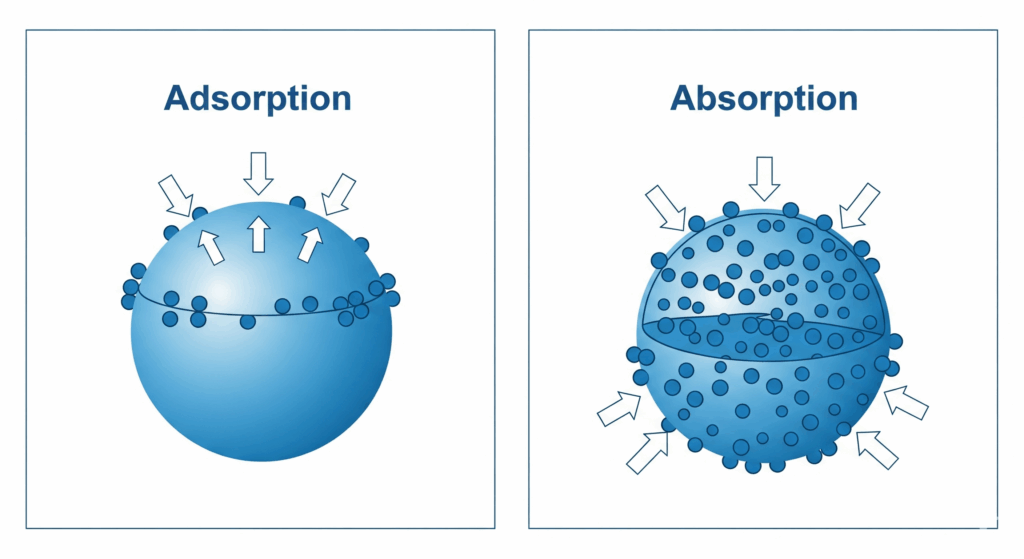

For any process engineer, understanding the precise mechanism of action is critical. The effectiveness of PAC relies on adsorption, a process often confused with absorption. The distinction is fundamental to understanding how the technology works.

- Adsorption: This is a surface-level phenomenon. Contaminant molecules in a liquid or gas are attracted to and adhere to the exterior surface of the activated carbon particle, much like static cling. The contaminant does not become part of the carbon itself. This process can be further divided into physical adsorption (physisorption), which involves weak intermolecular van der Waals forces, and chemical adsorption (chemisorption), which involves the formation of stronger, more permanent chemical bonds.

- Absorption: This is a volumetric process where a substance is drawn into and dissolves or permeates the entire volume of another material, like a sponge soaking up water.

Powdered activated carbon works exclusively through adsorption, using its immense surface area to capture unwanted molecules.

From Coconut Shells to High-Tech Carbon: The Activation Process

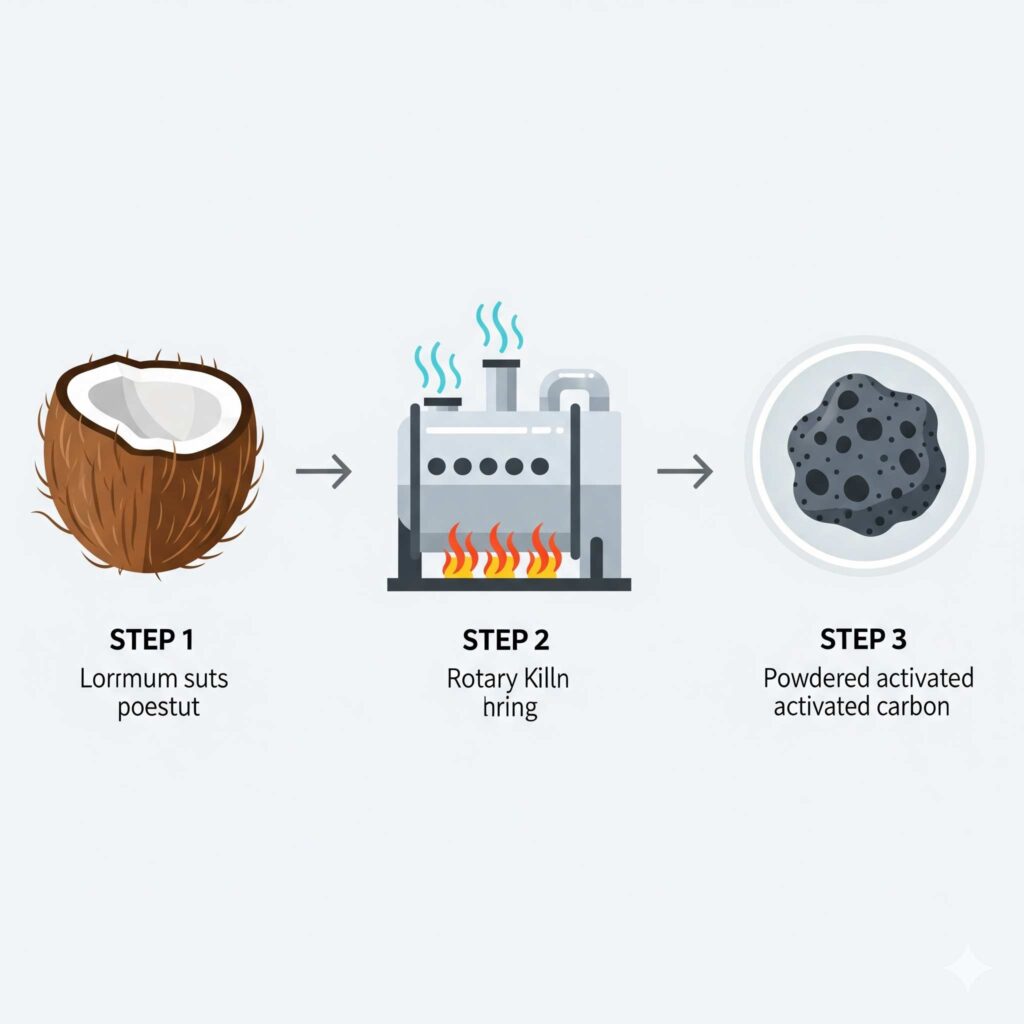

The unique properties of powdered activated carbon are not inherent to its raw materials. However, they are created through a meticulous, high-temperature manufacturing process. This “activation” transforms a simple carbon source into a high-performance adsorbent.

- Starting Materials: The process begins with carbon-rich organic materials. The most common sources are selected grades of coal, wood, and coconut shells. The choice of raw material is a critical factor that influences the final pore structure and performance characteristics of the PAC.

- Pyrolysis and Activation: The raw material is first superheated in a low-oxygen environment, a process called pyrolysis, to create a carbon “char.” This char is then “activated” by exposing it to steam at extremely high temperatures, typically between 900-1100°C, inside a large rotary or multiple-hearth kiln. The hot steam reacts with the carbon, etching away the internal structure to create a vast, interconnected network of microscopic pores, vastly increasing the internal surface area and creating the sites where adsorption will occur.

The Anatomy of PAC: How Key Properties Drive Performance

For a process engineer, evaluating a PAC product means looking beyond its appearance and understanding the technical specifications that dictate its performance. Three key properties are paramount.

| Property | Description & Importance |

|---|---|

| High Surface Area | The activation process creates a vast network of pores, resulting in a surface area exceeding 400 m²/g. This provides many sites for contaminants to adsorb, directly correlating to the carbon’s total capacity. |

| Pore Structure | The size and distribution of pores (micropores, mesopores, and macropores) are engineered by controlling the raw material and activation conditions. This allows for creating specific PAC grades tailored to adsorb molecules of different sizes and shapes, from small organic compounds to large color bodies. |

| Fine Particle Size | PAC particles are defined as being smaller than a U.S. standard 80 mesh sieve (<0.177 mm). This small particle size ensures that a large portion of the carbon’s surface area is on the exterior of the particle, leading to very rapid adsorption kinetics and enabling swift contaminant removal from a process stream. |

PAC in Action: Versatile Applications Across Industries

The science of adsorption, combined with the engineered properties of PAC, makes it one of the most versatile purification agents available. Its effectiveness is proven across a wide range of critical industrial applications.

- Municipal & Environmental Water Treatment: PAC is widely used to treat drinking water and wastewater. It effectively removes a broad spectrum of contaminants, including dissolved organic compounds that cause taste and odor issues, synthetic chemicals, and micropollutants.

- Air & Flue Gas Purification: PAC is a key technology for adsorbing harmful pollutants from industrial emissions in air treatment systems. It captures mercury, dioxins, and volatile organic compounds (VOCs) from flue gas streams.

- Food & Beverage Processing: Food-grade PAC is essential for purification in the food and beverage industry. Typical applications include decolorizing sugars and sweeteners, purifying edible oils, removing off-flavors from alcoholic beverages, and improving the quality of food additives.

- Pharmaceutical & Chemical Production: In high-purity applications, PAC is used to purify various products, including active pharmaceutical ingredients (APIs), antibiotics, vitamins, and other fine chemicals. It removes impurities and unwanted color bodies from intermediate and final products.

Suggested Call to Action (CTA):

Is your application unique? Explore our full range of custom-engineered PAC grades designed for your specific industry.

People Also Ask (FAQ Section)

1. What is the difference between activated carbon and regular charcoal?

Activated carbon has been processed at very high temperatures with an activating agent, like steam, to create a vast network of internal pores and an extremely high surface area. Regular charcoal does not undergo this activation process and therefore has a much lower surface area and significantly less adsorptive capacity.

2. Can powdered activated carbon be regenerated or reused?

No. Due to its fine particle size, PAC is designed for single-use applications. After it becomes saturated with contaminants, it is removed from the system and disposed of. Only Granular Activated Carbon (GAC) can typically be thermally regenerated for reuse.

3. Does the raw material (wood, coal, coconut) affect PAC performance?

Yes, absolutely. The raw material is a key factor determining the activated carbon’s final pore structure. For example, coconut shell-based carbons tend to have a high volume of small pores (micropores), which is ideal for specific applications. In contrast, wood-based carbons may have a different pore distribution better suited for removing larger color molecules.

4. How is PAC typically applied in a water treatment process?

PAC is usually mixed with water to create a slurry, which is then dosed directly into a contact tank or basin. After allowing sufficient contact time for adsorption, the spent carbon particles must be separated from the water, a step typically accomplished through sedimentation followed by a final polishing filter to capture any remaining fines.

Suggested Call to Action (CTA):

Have a complex purification challenge? Contact our engineering experts to discuss your process and find the optimal PAC solution.