Selecting the Right Adsorbent is More Than a Price Decision

In industrial water treatment, selecting the right granular activated carbon (GAC) is critical beyond a simple price comparison per ton. The choice of raw material—coal, coconut shell, or wood—fundamentally dictates the carbon’s physical properties and, consequently, its performance in a given application. For process engineers, plant operators, and purchasing managers, understanding these differences is key to ensuring system efficiency, meeting compliance standards, and managing long-term operational costs.

An incorrect choice can lead to poor contaminant removal, frequent media replacement, and higher-than-expected expenses. A data-driven approach, however, allows for selecting an adsorbent that is precisely matched to the facility’s target contaminants and operational realities. This guide provides a direct, technical comparison of the three primary types of activated carbon to help you make an informed, application-specific decision.

We will cover four key decision factors:

- Performance: How the internal pore structure of each carbon type affects its ability to adsorb specific contaminants.

- Durability: Why hardness is a critical factor in minimizing media loss and reducing long-term costs.

- Purity: How ash content impacts performance and its importance in high-purity applications.

- Cost: A look beyond the initial purchase price to a Total Cost of Ownership (TCO) analysis.

1. Meet the Contenders: A Profile of Each Carbon Type

Before diving into a detailed specification comparison, it’s essential to understand the fundamental characteristics of each carbon source.

Coal-Based Activated Carbon

Often considered the versatile workhorse of the industry, coal-based activated carbon is produced from raw materials like bituminous or anthracite coal. It is known for its balanced pore structure, containing a healthy mix of both small micropores and larger mesopores. This makes it highly effective for general-purpose water treatment, where it must remove a wide variety of organic contaminants in municipal and industrial wastewater.

Coconut Shell-Based Activated Carbon

Prized as the high-purity specialist, coconut shell-based carbon is a renewable, green material known for its exceptional physical properties. It is characterized by a predominantly microporous structure, extremely high hardness, and low ash content. These attributes make it the ideal choice for applications requiring the removal of small, dissolved organic molecules and for systems where durability and product purity are paramount.

Wood-Based Activated Carbon

Wood-based activated carbon is the decolorizing expert. Produced from renewable sources like sawdust, its activation results in a highly macroporous structure, meaning it has a greater volume of huge pores. This makes it exceptionally effective at removing large color bodies and complex organic molecules from liquids, a common requirement in the food and beverage and chemical processing industries.

2. Head-to-Head: A Comprehensive Technical Specification Comparison

The most effective way to compare these materials is to look at their key technical specifications. The differences in these parameters directly and significantly impact how the carbon will perform in an industrial water treatment setting.

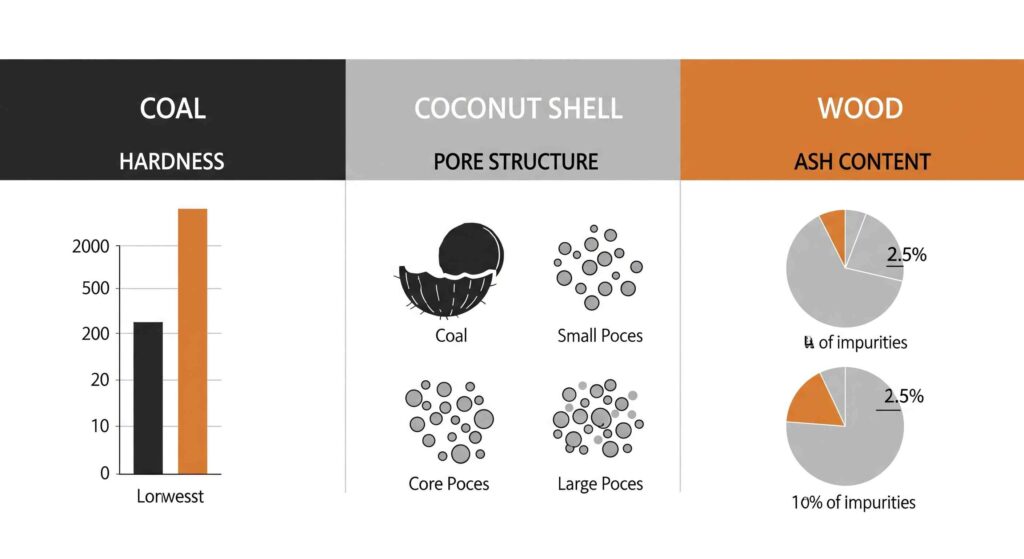

| Characteristic | Coal-Based (Bituminous) | Coconut Shell-Based | Wood-Based |

|---|---|---|---|

| Dominant Pore Structure | Balanced mix of micropores and mesopores | Primarily micropores | Primarily mesopores and macropores |

| Hardness / Abrasion Number (%) | High (90 – 95%) | Very High (>98%) | Low (~85%) |

| Ash Content (%) | Medium to High (8 – 18%) | Very Low (<5%) | High (~15%) |

| Bulk Density (g/cc) | High (0.38 – 0.48) | Very High (0.48 – 0.58) | Low (0.25 – 0.30) |

| Typical Iodine Value (mg/g) | 800 – 1100 | 900 – 1200 | Generally lower, focused on larger pores |

| Key Advantage in Water Treatment | Versatility for a wide range of organic contaminants. 10 | Superior removal of small, dissolved organics; high purity | Excellent for decolorization of large molecules |

3. Performance Deep Dive: What the Specs Mean for Your Water Treatment System

The numbers in the table above are not just abstract data points; they translate directly into real-world performance, durability, and purity within your water treatment system.

Adsorption Capacity (Pore Structure)

The type of pores in an activated carbon determines which contaminants it can effectively remove.

- The predominantly microporous structure of coconut shell carbon makes it a specialist at removing small, dissolved organic molecules like trihalomethanes (THMs), pesticides, and other disinfection byproducts. The small pores provide high-energy adsorption sites that are perfectly sized to capture and hold these specific contaminants.

- Coal-based carbon’s balanced micro- and mesoporous structure makes it a versatile all-rounder. It can effectively remove the smaller molecules that fit into its micropores and the medium-sized organic compounds typically found in industrial effluent that are better captured by its mesopores.

Operational Durability (Hardness)

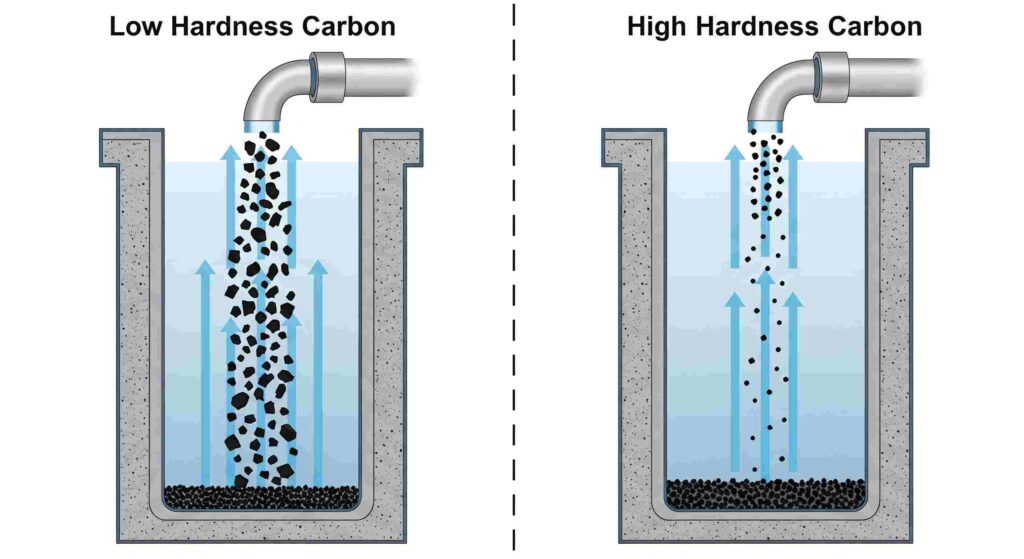

The Hardness or Abrasion Number is a critical measure of the carbon’s ability to withstand the physical stress of backwashing.

- Coconut shell carbon is highly durable with a hardness number typically exceeding 98%. This high mechanical strength means it experiences negligible material loss during the vigorous, high-flow backwashing cycles required to clean the filter bed. This translates to a longer media lifespan and more consistent bed depth.

- Coal-based carbon is also tough (90-95%) and holds up well in most industrial applications. However, softer carbons, like wood-based, are less suitable for systems that require frequent and aggressive backwashing, as they will break down more quickly, leading to material loss and potential clogging.

Purity and Leachables (Ash Content)

Ash is the non-carbon, inorganic material within the GAC, acting as an impurity.

- The very low ash content (<5%) of coconut shell carbon makes it the material of choice for high-purity water applications, such as in process water for the food, beverage, or pharmaceutical industries, or as pre-treatment for RO systems. Low ash means higher carbon purity, greater available pore space for adsorption, and a minimal risk of leaching inorganic compounds like metal oxides into the treated water.

- The higher ash content of coal and wood-based carbons is generally acceptable for standard wastewater or municipal water treatment. However, it makes them less suitable for applications where trace contaminants are a concern.

4. The Economic Equation: A Total Cost of Ownership (TCO) Analysis

For purchasing managers, the decision often comes down to cost. However, a sophisticated analysis must look beyond the initial price per ton to the Total Cost of Ownership (TCO) over the media’s entire lifecycle.

Initial Cost vs. Lifetime Value

On a per-pound basis, coconut shell activated carbon often has a higher initial purchase price than its coal-based counterpart. However, this initial outlay does not account for the operational costs accumulated over time.

The Cost of Attrition

The most significant operational cost related to GAC is the replacement of media lost during backwashing. A less-hard carbon will physically break down (a process called attrition), and these fine particles will be washed out to the drain. This requires more frequent “topping off” or complete replacement of the carbon bed. A stiffer, more durable carbon-like coconut shell minimizes this loss, lowering long-term material and labor costs.

Regeneration and End-of-Life

The ability to thermally regenerate spent activated carbon can significantly impact TCO by reducing disposal costs and the need to purchase virgin material. More durable carbons, which can better withstand the high temperatures and physical stress of the regeneration process, are a better long-term investment for facilities that plan to regenerate their media.

A TCO calculation should include:

- The initial purchase price of the carbon.

- Freight and installation costs.

- Projected media replacement cost due to attrition (Hardness is the key factor here).

- Pumping costs (related to density and pressure drop).

- Regeneration or disposal costs at the end of the service life.

5. The Decision Framework: Which Carbon is Right for Your Application?

The “best” activated carbon is the one that is correctly matched to your specific water treatment challenge. Use this framework to guide your decision.

Choose Coal-Based Activated Carbon if…

Your primary need is the general removal of a wide range of mixed organic contaminants, such as those found in municipal or industrial wastewater treatment. It offers a versatile and cost-effective solution when the absolute highest purity is not required, and achieving a lower initial purchase cost is a key driver.

Choose Coconut Shell-Based Activated Carbon if…

Your application demands high purity, such as in process water for the food, beverage, or pharmaceutical industries, or as pre-treatment for RO systems. It is the superior choice when removing small, specific organic molecules (e.g., THMs, pesticides) and when long-term durability and minimizing media loss are critical economic factors.

Choose Wood-Based Activated Carbon if…

Your primary and specific goal is to decolorize liquids by removing large organic color bodies. While less common in typical industrial water treatment, this is a critical application in specialized processes within the food and chemical industries.

Making a Data-Driven, Application-Specific Choice

No single “best” type of activated carbon exists for all industrial water treatment scenarios. The optimal choice is a trade-off between performance, durability, and cost. Coal-based carbon offers unmatched versatility for general applications, wood-based carbon excels at decolorization, and coconut shell-based carbon provides superior durability and purity for the most demanding applications. By analyzing the technical data and considering the total cost of ownership, engineers and managers can select the ideal adsorbent that meets their technical requirements, aligns with their financial priorities, and ensures the long-term success of their water treatment system.