In industrial procurement, few decisions carry as much weight as selecting a raw material supplier. When that material is activated carbon, the stakes are even higher. A substandard batch can lead to catastrophic product failure, costly production shutdowns, and significant damage to your brand’s reputation. While a product specification sheet provides a starting point, it doesn’t tell the whole story. Proper quality assurance and risk management lie in a deep understanding of the standards and certifications that govern the manufacturing process.

This guide is designed for procurement managers, quality assurance professionals, and regulatory compliance officers in high-stakes industries. It moves beyond the marketing claims to provide a clear, authoritative framework for vetting suppliers and ensuring the activated carbon you source is compliant and consistently safe, effective, and reliable.

Beyond the Spec Sheet: Why Certifications are Your First Line of Defense in Risk Management

In a competitive market, the temptation to select a supplier based on price alone is strong. However, an uncertified or poorly vetted activated carbon supplier introduces an unacceptable level of risk into your supply chain. Certifications are not merely logos on a website; they are your first and most important line of defense against process failure and regulatory non-compliance.

Prioritizing certified activated carbon is a strategic business decision directly impacting your bottom line. It is a critical tool for:

- Mitigating Catastrophic Risk: In industries like municipal water treatment or food and beverage production, a contaminated batch of activated carbon can have public health consequences, leading to product recalls and severe legal liabilities.

- Ensuring Supply Chain Resilience: Certified suppliers are audited for process consistency and traceability, reducing the likelihood of unexpected batch failures that can halt your production lines.

- Protecting Brand Reputation: Your final product is only as pure as the materials used. Aligning with certified, reputable suppliers protects your brand’s commitment to quality and safety.

- Optimizing Total Cost of Ownership (TCO): The slightly higher upfront cost of fully certified activated carbon is a sound investment against a single quality failure’s potentially devastating financial impact. A reliable product from a certified source prevents costly rework, product loss, and downtime.

The Foundation of Quality: Understanding ISO 9001 and General Manufacturing Standards

One of the first credentials you will encounter when evaluating suppliers is ISO 9001. It is crucial to understand that ISO 9001 is not a product certification but a process certification. It does not guarantee that a specific batch of activated carbon will meet your technical specifications. Instead, it certifies that the manufacturer has a robust, documented, and audited Quality Management System (QMS).

An ISO 9001 certification tells you that a potential supplier is committed to:

- Consistency: They have defined and repeatable processes for every stage of manufacturing, from raw material intake to final packaging.

- Traceability: They can trace a specific batch of finished product back through the production process to the raw materials used.

- Customer Focus: Their system is designed to meet customer requirements and enhance customer satisfaction.

- Continuous Improvement: They must regularly review and improve their processes to prevent errors and enhance quality.

Think of ISO 9001 as the foundation for all other product- and application-specific certifications. A supplier without it may be able to produce a good batch. However, they lack a verified system to do so consistently over the long term.

Critical Application Certifications: Matching the Standard to Your Industry

While ISO 9001 provides a baseline, the most critical certifications apply directly to your specific industry and application. Sourcing activated carbon without the proper application-specific credentials is a significant compliance risk. The following table outlines the key standards you must look for in highly regulated sectors.

| Standard/Certification | What It Guarantees | Primary Industry Application |

|---|---|---|

| NSF/ANSI 61 | The product is safe for treating drinking water and will not leach harmful contaminants into the water supply. | Municipal Water Treatment, Point-of-Use Water Filters, Beverage Production |

| ISO 22000 | The manufacturer has a certified food safety management system to identify and control food safety hazards, preventing contamination. | Food & Beverage, Pharmaceuticals. |

| Food Chemicals Codex (FCC) | The product meets internationally recognized purity and identity standards for use as a food additive or in direct contact with food during processing. | Food & Beverage, Sweetener Decolorization |

| Kosher & Halal | The product and the manufacturing process have been audited and certified to follow specific religious dietary laws. | Food & Beverage, Pharmaceuticals |

| ASTM Standards | The product has been tested using standardized, repeatable procedures for measuring key physical and performance properties. | Industrial Air & Gas Purification, Quality Control, Supplier Comparison |

![]()

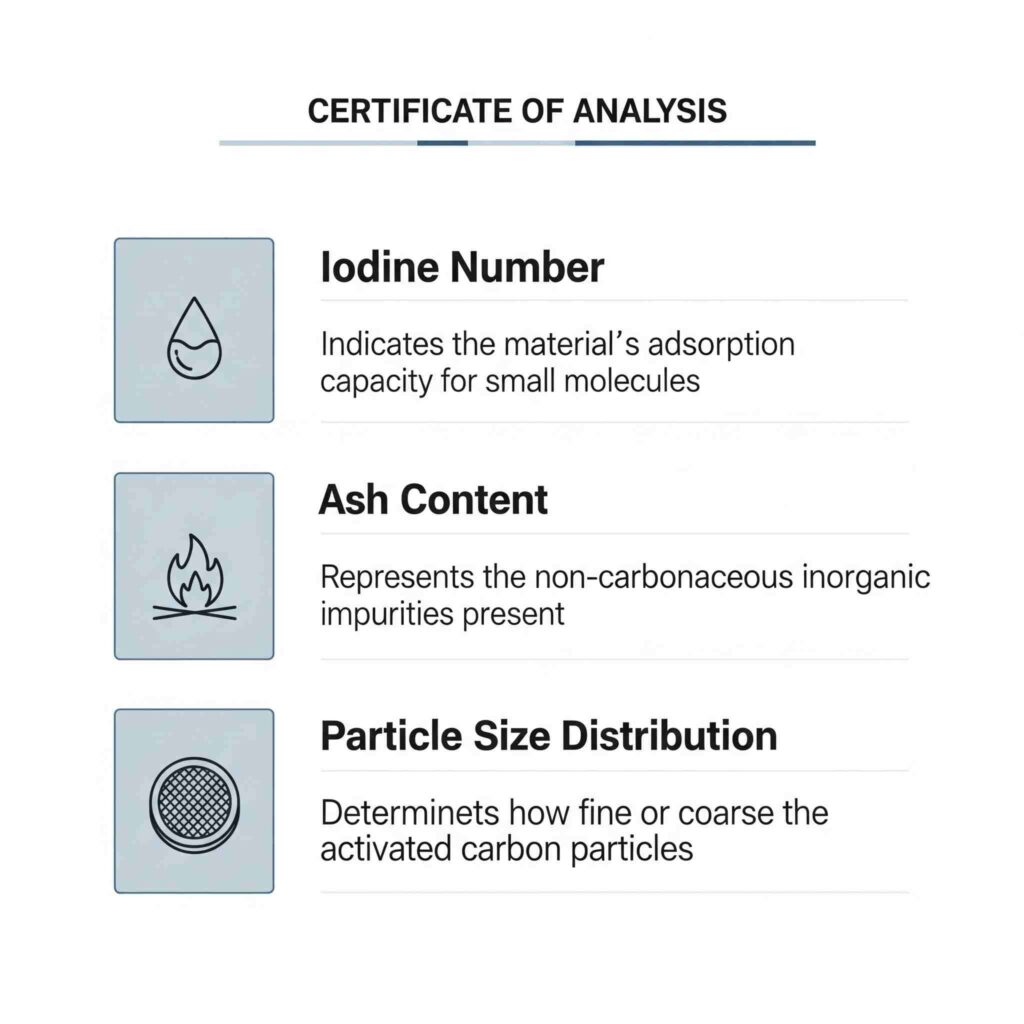

How to Read a Certificate of Analysis (COA): Verifying Quality, Batch by Batch

Certifications prove a supplier’s capabilities, but the Certificate of Analysis (COA) provides the ultimate proof of quality for the specific lot being delivered to your facility. Every shipment of activated carbon should be accompanied by a COA detailing its performance against key parameters. Understanding how to interpret this document is a non-negotiable skill for any procurement professional.

Key parameters to scrutinize on a COA include:

- Iodine Number: This is a fundamental measure of the activated carbon’s microporosity and its ability to adsorb small molecules. A higher iodine number generally indicates a higher degree of activation and a greater capacity for removing contaminants like those responsible for taste and odor in water.

- Ash Content: This represents the non-carbon, inorganic material remaining after combustion. A lower ash content indicates a purer carbon product, which is critical in applications where leaching of inorganic contaminants is a concern.

- Mesh Size / Particle Size Distribution: This determines the carbon’s hydraulic properties and reaction kinetics. The particle size must match your system’s design to ensure proper flow rates and prevent excessive pressure drop.

- Lot/Batch Number: This is the most critical component for traceability. In the event of an issue, the lot number allows you and your supplier to trace the product back to its exact production date and raw material source.

The Supplier Qualification Checklist: Key Questions to Ask Before Signing the Contract

A truly rigorous supplier audit goes beyond simply collecting certificates. Use this checklist of probing questions to assess a potential partner’s genuine commitment to quality control.

- “Can you provide a copy of your current, unexpired certificate from the accredited third-party certifying body?” Do not accept an expired certificate or a simple claim of compliance.

- “What is your documented process for qualifying and testing incoming raw materials?” The starting material’s quality determines the final product’s quality, whether it’s coconut shell, coal, or wood.

- “Can you walk me through your in-process quality control checkpoints during carbonization and activation?” A reliable manufacturer will have multiple sampling and testing points throughout production to ensure standards are met.

- “How do you ensure lot-to-lot traceability from the raw material source to the final packaged product?” Ask to see an example of their traceability documentation.

- “Can you provide COAs from three recent production lots to demonstrate lot-to-lot consistency?” This allows you to verify that their process delivers a consistent product over time.

People Also Ask: Your Activated Carbon Certification Questions Answered

1. Is all activated carbon the same?

Absolutely not. The properties and performance of activated carbon depend highly on the raw material used (e.g., coconut shell, coal, wood) and the specific activation process (e.g., steam or chemical activation). Coconut shell-based carbon, for example, has a high proportion of micropores, making it ideal for removing trace organic contaminants in drinking water. In contrast, coal-based carbon may be better suited for color removal or gas-phase applications. This is why application-specific certifications are so critical.

2. What is the difference between NSF/ANSI 42 and NSF/ANSI 61?

This is a crucial distinction in water treatment. NSF/ANSI 42 is certified for aesthetic effects, meaning the product is certified to reduce non-health-related contaminants like chlorine, taste, and odor. NSF/ANSI 61 is the critical health effects standard, certifying that the product will not leach harmful pollutants into the water it treats. NSF/ANSI 61 is the essential standard for any municipal or potable water application.

3. Can a supplier be “FDA Compliant”?

This phrasing requires clarification. The U.S. Food and Drug Administration (FDA) does not “approve” or “certify” activated carbon itself. However, manufacturing facilities can be registered with the FDA. The activated carbon they produce can be certified as meeting the Food Chemicals Codex (FCC) standards, which the FDA recognizes for materials used in food applications. Always ask for the specific certification (e.g., FCC), not a vague claim of “FDA compliance.”

4. Does USDA Organic certification apply to activated carbon?

Yes, in specific circumstances. Activated charcoal (carbon) is included on the National List of Allowed and Prohibited Substances for use in organic livestock production as a medical treatment. Therefore, if you supply the organic agriculture industry, you must source activated carbon from a supplier that can provide this certification.

Navigate Compliance with Confidence. Sourcing the right activated carbon is a complex, high-stakes decision. Schedule a no-obligation consultation with our Quality & Compliance specialists to discuss your application needs and ensure your supply chain is secure.