Coal vs. Coconut vs. Wood Activated Carbon: A Data-Driven Comparison for Industrial Water Treatment

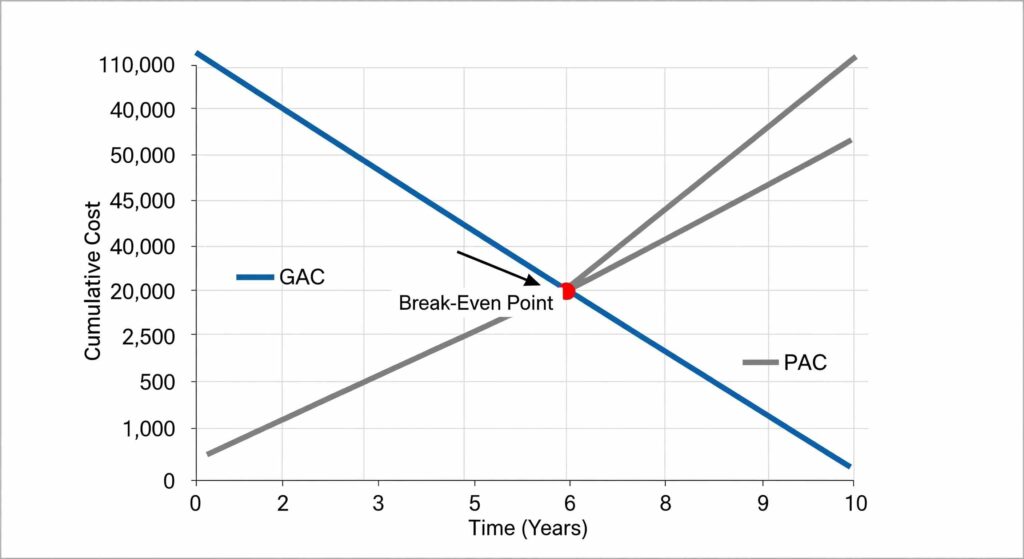

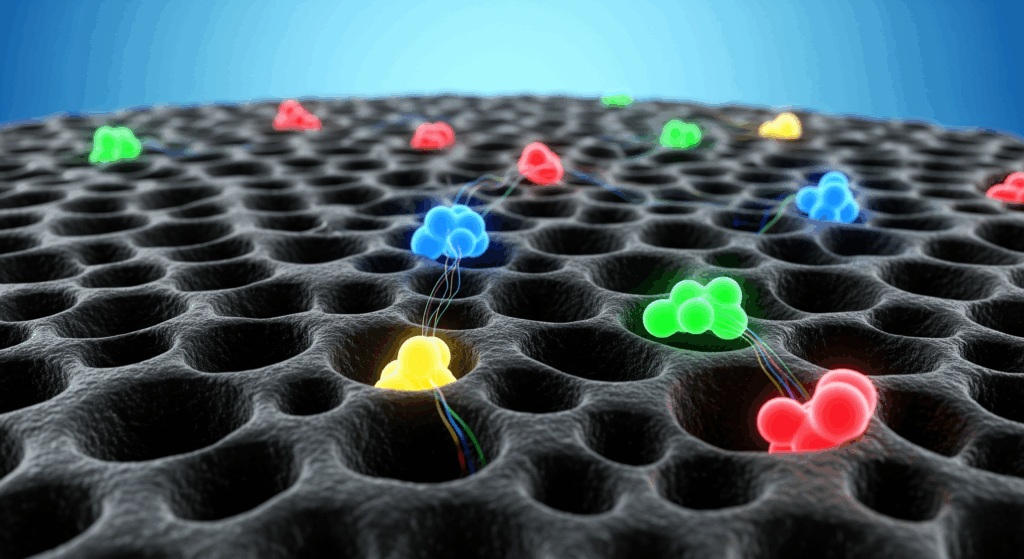

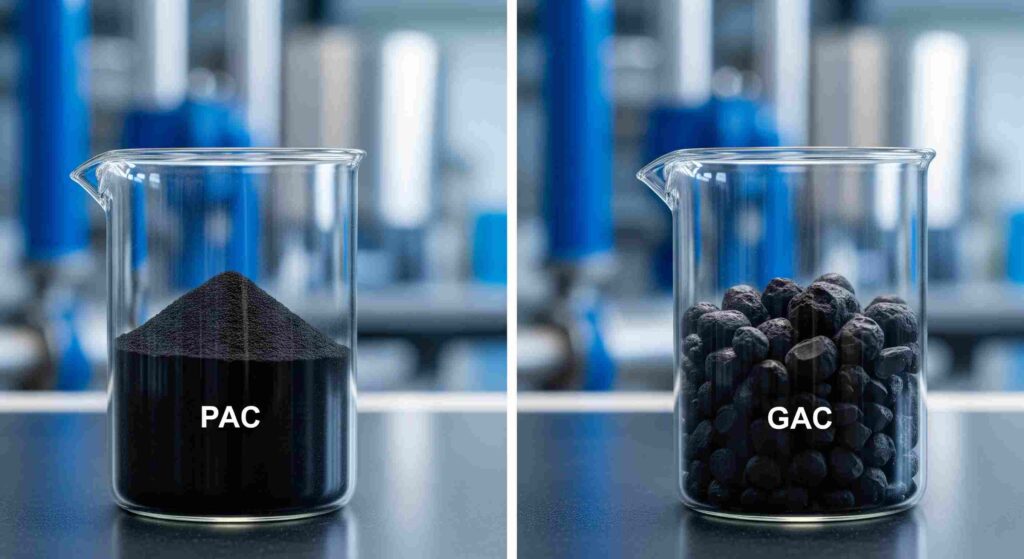

Selecting the Right Adsorbent is More Than a Price Decision In industrial water treatment, selecting the right granular activated carbon (GAC) is critical beyond a simple price comparison per ton. The choice of raw material—coal, coconut shell, or wood—fundamentally dictates the carbon’s physical properties and, consequently, its performance in a given application. For process engineers, […]