Modern industry runs on purity. Whether you are managing municipal water treatment, scrubbing mercury from flue gas, or decolorizing pharmaceutical intermediates, the efficiency of your process often hinges on a single, porous variable: the quality of your filtration media. As an industrial activated carbon manufacturer, we understand that carbon is not a commodity—it is a critical engineering component. When supply chains fracture or batch quality drifts, your compliance and operational costs suffer immediately.

We exist to close that gap. By controlling the entire production lifecycle—from the sourcing of raw carbonaceous material to the final activation kinetics—we provide what traders and distributors cannot: absolute consistency and technical accountability.

How Raw Materials Dictate Performance

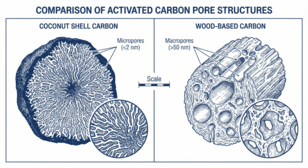

The journey to high-performance filtration begins long before the material enters the kiln. The widely held misconception is that “carbon is carbon,” but the physical origin of the char dictates the pore structure of the final product. We meticulously select raw materials based on the target molecule you need to capture.

For instance, when our clients require the removal of volatile organic compounds (VOCs) or taste and odor compounds from water, we utilize coconut shell charcoal. Its natural density creates a vast network of micropores—tiny traps perfect for adsorbing small molecules. Conversely, for decolorization tasks in the food and beverage sector, we shift to wood-based carbon, which inherently develops macropores capable of capturing large color bodies. Bituminous coal, the workhorse of industrial filtration, offers a balanced structure ideal for a wide range of wastewater and gas phase applications.

Understanding this raw material hierarchy is the first step in ensuring your filtration system operates efficiently. However, the raw potential of these materials is only unlocked through precise thermal processing.

Where Science Meets Intense Heat

Transforming raw char into an active adsorbent requires a delicate balance of temperature, time, and atmosphere. This is where our role as a manufacturer becomes pivotal. Unlike simple crushing and screening operations, we employ rotary kilns operating at temperatures exceeding 900°C to “open” the carbon structure.

Our primary method, steam activation, utilizes steam as a selective oxidizing agent. It eats away the amorphous carbon, drilling billions of microscopic pores into every granule. This process creates the massive internal surface area—often exceeding 1,000 m²/g—that defines high-quality granular activated carbon (GAC). By adjusting the residence time in the kiln, we can fine-tune this pore distribution, shifting the balance between adsorption capacity and mechanical hardness.

For specific high-purity applications, we may employ chemical activation using phosphoric acid or zinc chloride. This produces a carbon with an extremely open pore structure, often preferred in powdered forms (PAC) for liquid phase purification. But creating these pores is only half the battle; verifying that they work for your specific application is where our laboratory takes over.

Beyond the Standard Datasheet

In the activated carbon market, a datasheet is often treated as a guarantee. In reality, it should be treated as a starting point. Specifications can drift significantly between production runs if not monitored by a rigorous internal lab. We validate every batch against ASTM standards to ensure the material you receive performs exactly as the pilot test predicted.

Key performance indicators we monitor include:

Número de iodo: The industry standard for measuring microporosity. A high iodine number indicates a high capacity for small molecules, but we balance this against hardness to prevent attrition.

Número do melaço: Critical for applications involving larger molecules (like color removal), measuring the carbon’s ability to adsorb complex structures.

Hardness & Abrasion Number: Essential for GAC used in reactivated systems or deep bed filters, where soft carbon would crumble into dust and block flow.

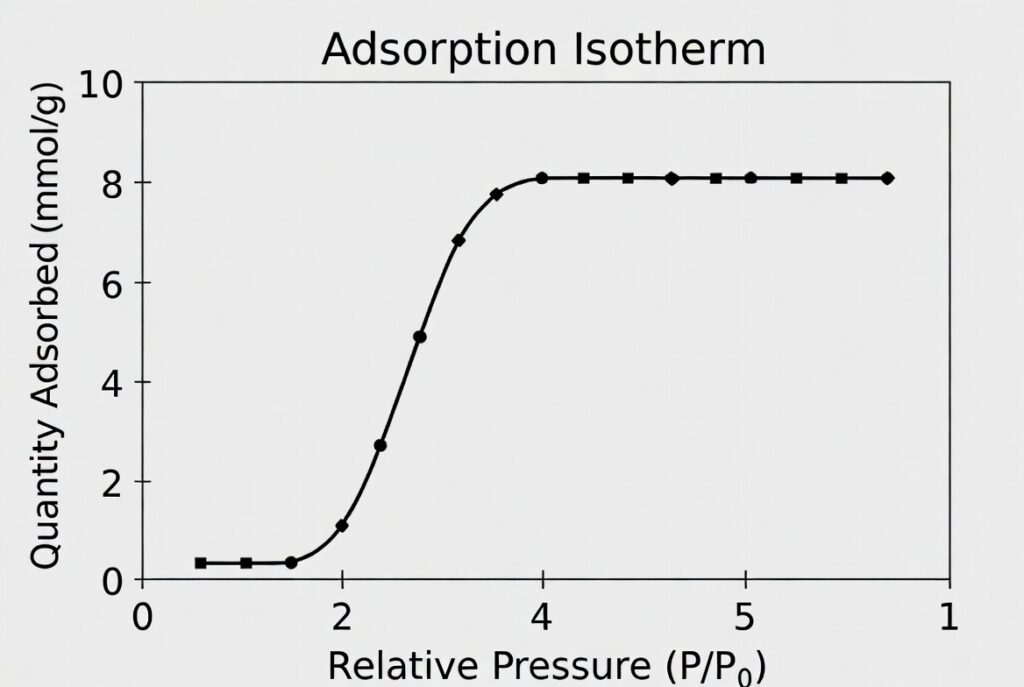

We don’t just test for compliance; we test for prediction. By analyzing the adsorption isotherms, we can model how long a bed will last before breakthrough occurs in your specific stream. This data-driven approach removes the guesswork from changeout schedules.

Custom Impregnation & Specialized Blends

Standard carbon is incredibly versatile, but some contaminants—like hydrogen sulfide (H2S), ammonia, or mercury—are not easily captured by physical adsorption alone. For these challenges, we transition from physical filtration to chemisorption.

Through our custom impregnation line, we can chemically treat the internal surface of the carbon. For example, impregnating carbon with potassium hydroxide (KOH) or sodium hydroxide (NaOH) significantly enhances its affinity for acidic gases like H2S. This process, known as custom activated carbon manufacturing, allows us to engineer a media that doesn’t just trap the contaminant but chemically reacts with it, locking it permanently into the pore structure. This is vital for biogas desulfurization and odor control in municipal wastewater plants where “nuisance odors” are a regulatory liability.

Supply Chain Security & Global Logistics

The best engineering in the world is useless if the product is stuck in a container halfway across the ocean. In recent years, global logistics volatility has forced procurement managers to rethink their reliance on single-origin suppliers.

We address this risk through a multi-sourcing strategy and strategic warehousing. We maintain bulk inventory of critical GAC and PAC grades at regional distribution hubs. This allows us to buffer against upstream disruptions and offer “Just-in-Time” delivery for urgent plant turnarounds. Whether you need 500 kg super sacks or pneumatic tanker deliveries for silo filling, our logistics team coordinates the freight to ensure your plant never has to throttle down due to media shortages.

Reactivation & Sustainability Services

Sustainability is no longer a buzzword; it is a procurement mandate. To support your Environmental, Social, and Governance (ESG) goals, we offer carbon reactivation services. Instead of sending spent carbon to a landfill, we can thermally reactivate it—burning off the adsorbed contaminants and restoring the carbon’s porosity for reuse. This closes the loop, significantly reducing your carbon footprint and lowering long-term operational costs.

Frequently Asked Questions (FAQ)

Q: What is the difference between GAC and PAC? Carvão ativado granular (GAC) consists of larger particles suitable for fixed-bed filters where water or gas flows through the media. Carvão ativado em pó (PAC) is fine dust added directly to a process stream (like a mixing tank) and later filtered out. GAC is typically reusable/reactivatable, while PAC is usually single-use.

Q: How do I know which mesh size to choose? Mesh size affects both flow rate and adsorption kinetics. Finer mesh sizes (e.g., 12×40) offer faster adsorption rates but create higher pressure drop (head loss). Coarser sizes (e.g., 8×30) allow for better flow but react slightly slower. We calculate the optimal balance based on your vessel design and flow rate.

Q: Can you match a competitor’s activated carbon specification? Yes. If you provide a datasheet or a physical sample of the media you are currently using, our lab can analyze its density, activity level, and particle distribution to manufacture an equivalent or superior replacement, often with better supply terms.

Q: Do you offer NSF-certified carbon for drinking water? Absolutely. We manufacture grades that are certified to NSF/ANSI Standard 61, ensuring they are safe for the treatment of drinking water and free from harmful leachables.

The Partner You Need for Critical Filtration

Sourcing activated carbon is not just about finding the lowest price per kilogram; it is about securing a predictable, high-performance outcome for your process. From selecting the right coconut or coal base to verifying the iodine number in our lab, every step we take is designed to reduce your operational risk.

Do not leave your filtration compliance to chance or spot-market availability. Partner with a manufacturer that prioritizes technical transparency and supply chain resilience.

Request a Technical Consultation: Connect with our engineers to discuss your specific filtration challenge and get a custom quote.