In water and chemical purification, choosing an adsorbent medium is a critical decision with far-reaching consequences for operational efficiency, regulatory compliance, and budget allocation. Among the most effective technologies is activated carbon, a material prized for its vast surface area and remarkable ability to adsorb a wide range of contaminants. However, the decision is not as simple as merely specifying “activated carbon.” The primary deliberation often comes down to two principal forms: Powdered Activated Carbon (PAC) and Granular Activated Carbon (GAC).

Consequently, selecting the appropriate form is not just a technical detail but a strategic choice. An incorrect decision can lead to inefficient treatment, higher operational costs, and complex handling challenges. Therefore, this guide provides a definitive, data-driven comparison to empower engineers, plant managers, and procurement specialists to make the most informed decision for their application.

Foundational Differences: What Sets PAC and GAC Apart?

Although derived from the same carbonaceous source materials and activated through similar processes, the fundamental distinction between PAC and GAC lies in their physical form, which dictates their application and performance characteristics. Understanding these core differences is the first step in the selection process.

Physical Characteristics: Particle Size and Surface Area

The most apparent difference is particle size. Powdered Activated Carbon consists of fine particles, typically less than 0.177 mm in diameter (passing an 80-mesh sieve). This fine granulation creates an enormous external surface area immediately available for adsorption. In contrast, Granular Activated Carbon has a larger, more defined particle size, ranging from 0.2 to 5 mm. While its internal porous structure is vast, its external surface area is significantly smaller than that of an equivalent mass of PAC. This distinction directly impacts the rate of adsorption.

Manufacturing and Material Forms

PAC and GAC are produced from coal, coconut shells, or wood. The activation process creates a network of microscopic pores, but the final step differs. For PAC, the carbon is ground into a fine powder. For GAC, it is crushed and sieved to specific size ranges. As a result, PAC is delivered as a bulk powder, often in bags or super sacks. At the same time, GAC is supplied as uniform granules suitable for packing into large filter vessels.

Application and Dosing: How They Work in Practice

The physical forms of PAC and GAC directly translate into vastly different methods of application and integration into treatment systems. One is designed for rapid, short-term contact, while the other is engineered for long-term, continuous filtration.

PAC Systems: Slurry-Based, Short-Contact Applications

Engineers typically apply PAC in a slurry form, where the powder is mixed with water and dosed directly into the treated water stream. This method is designed for systems with a short contact time. Because of its massive, readily accessible surface area, PAC adsorbs contaminants very quickly. Subsequently, the carbon must be removed from the water through coagulation, flocculation, sedimentation, or membrane filtration. This makes PAC an ideal solution for seasonal problems, such as taste and odor events caused by algae blooms, or for emergency response to chemical spills.

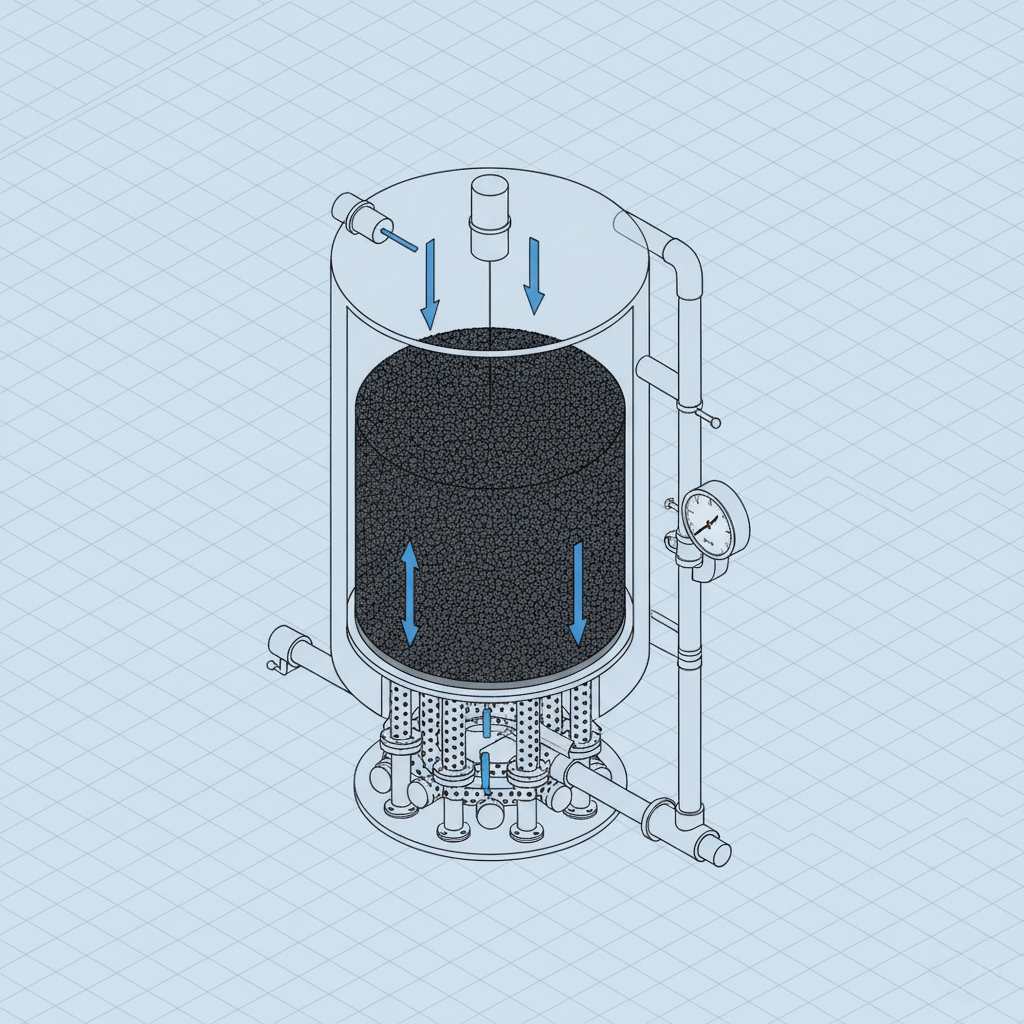

GAC Systems: Fixed-Bed Filters for Continuous Treatment

Conversely, GAC is a filtration medium within large vessels or columns, known as contactors. Water passes through a stationary “bed” of granular carbon, simultaneously filtering out particulates and adsorbing dissolved organic contaminants. This fixed-bed configuration is designed for continuous, long-term operation. It serves as a polishing step to consistently meet stringent water quality standards. GAC systems represent a more permanent infrastructure installation compared to the more transient nature of PAC dosing systems.

Performance Deep Dive: A Head-to-Head Comparison

When evaluating PAC versus GAC for a specific treatment objective, directly comparing their performance metrics is essential. The choice involves trade-offs between speed, capacity, and operational requirements.

Adsorption Rate and Kinetics

Due to its greater external surface area, PAC exhibits significantly faster adsorption kinetics. It can rapidly reduce concentrations of target contaminants in minutes. GAC works more slowly, requiring a longer contact time—often hours—as water percolates through the filter bed. However, what GAC lacks in speed, it makes up for in capacity and longevity.

Contaminant Removal Efficiency

Both forms are highly effective, but their efficiency profiles differ. PAC is exceptionally effective at quickly removing high concentrations of contaminants, making it superior for acute events. GAC excels at removing contaminants to very low, often non-detectable, levels over a long period. It is the preferred choice for polishing effluent and ensuring consistent compliance for a broad spectrum of trace organic compounds.

Handling and Operational Complexity

Handling PAC can be challenging due to the potential for dust, which requires specialized handling equipment and personal protective equipment (PPE) for operators. Dosing systems also require precise calibration to manage slurry concentrations. Conversely, GAC systems are relatively simple to operate once installed. However, the initial loading of carbon into large vessels is a significant undertaking, as is the eventual removal and replacement of the spent media.

A Comparative Table: PAC vs. GAC at a Glance

| Feature | Powdered Activated Carbon (PAC) | Granular Activated Carbon (GAC) |

|---|---|---|

| Particle Size | Very fine (<0.177 mm) | Larger granules (0.2-5 mm) |

| Adsorption Rate | Speedy (minutes) | Slower (hours) |

| Application | Dosed as a slurry for short-contact | Used in fixed-bed filters for continuous flow |

| Capital Cost | Low (dosing pumps, mixers) | High (large vessels, piping, infrastructure) |

| Operational Cost | High (consumable, single-use) | Lower (long media life, potential for reactivation) |

| Best For | Seasonal issues, spills, and acute events. | Continuous polishing, long-term compliance |

| Handling | Dust control required | Simpler operation, but heavy media handling |

| Lifecycle | Single-use, removed via sludge. | Can often be reactivated and reused |

Financial and Long-Term Considerations

Beyond technical performance, the economic and lifecycle implications of choosing PAC or GAC are paramount. The decision impacts both initial capital budgets and long-term operational expenses.

Capital Expenditure (CapEx) vs. Operational Expenditure (OpEx)

PAC systems generally have a much lower initial CapEx. The required equipment—storage silos, slurry tanks, and dosing pumps—is relatively inexpensive compared to the large-scale infrastructure needed for GAC. However, PAC is a consumable chemical, leading to higher, recurring OpEx based on dosage rates.

GAC systems are the inverse. They require a significant upfront CapEx for the large contactor vessels, piping, and initial carbon fill. Once operational, however, the OpEx can be lower, as the carbon bed can last for months or even years before needing replacement, resulting in lower consumables and labor costs over the long term.

Reactivation and Disposal: The Carbon Lifecycle

A significant long-term advantage of GAC is the potential for reactivation. Once a GAC bed is “spent” or saturated with contaminants, the carbon can be removed and transported to a specialized high-temperature furnace. There, the adsorbed contaminants are destroyed, and the carbon’s porous structure is restored, allowing it to be reused. This process significantly reduces disposal costs and improves the sustainability of the operation. PAC, in contrast, is a single-use product. Once it has adsorbed contaminants, it is removed with the sludge from the clarification process. It must be disposed of in a landfill.

Making the Right Choice for Your Facility

Ultimately, the choice between PAC and GAC is not about which is “better” in a vacuum, but which is the optimal tool for a specific job. The decision should be driven by a clear assessment of the treatment goals, source water characteristics, and operational constraints.

When to Choose PAC: Key Scenarios and Use Cases

Powdered Activated Carbon is the superior choice in the following situations:

- Seasonal Contaminants: For treating predictable, short-duration events like seasonal taste and odor from algae blooms.

- Emergency Response: For rapid deployment to address unexpected chemical spills or contamination events.

- Low Capital Budgets: When upfront investment in infrastructure is a primary constraint.

- Existing Clarification Infrastructure: For facilities that can easily add a dosing system ahead of existing coagulation and sedimentation processes.

Simulated Case Study: A municipal water utility experiences severe taste and odor complaints for two months every summer due to geosmin produced by algae. Instead of investing in an extensive GAC filtration system that would be underutilized most of the year, they install a cost-effective PAC dosing system that runs only during the problem season, effectively resolving the issue with minimal capital outlay.

When to Choose GAC: Key Scenarios and Use Cases

Granular Activated Carbon is the ideal solution under these circumstances:

- Continuous Contamination: For source water with persistent, low-level organic contaminants that require constant removal.

- Stringent Polishing Requirements: When the goal is to achieve extremely low effluent concentrations for compounds like industrial solvents or pesticides.

- Long-Term Solutions: For new plant designs or major upgrades where a permanent, reliable treatment barrier is required.

- Sustainability Goals: When carbon reactivation and reuse are essential operational and environmental objectives.

Simulated Case Study: An electronics manufacturing plant produces a consistent wastewater stream containing trace solvents. As a final polishing step, they install a series of GAC contactors to meet strict discharge permits. The system reliably removes the target contaminants 24/7, and the plant contracts a service to exchange and reactivate the carbon annually, creating a sustainable, long-term compliance solution.

Partnering with an Expert for a Custom Solution

The decision between PAC and GAC involves a complex interplay of technical, operational, and financial variables. While this guide provides a framework, every application is unique. Partnering with an activated carbon specialist is the most effective way to analyze your specific needs, conduct pilot testing, and design a solution that is effective and economically optimized for the long term. To ensure you select the best activated carbon solution for your facility, request a consultation with our engineering team today.