Understanding the journey of coal-based activated carbon from a raw mineral to a high-performance purification medium is essential for engineers, procurement managers, and plant operators. The manufacturing process is not merely a production line; it is a highly controlled engineering discipline where every step directly influences the final product’s performance, consistency, and suitability for a specific application. A thorough grasp of this process empowers professionals to make more informed sourcing decisions, troubleshoot system performance, and ultimately, achieve better results. This guide provides a comprehensive, step-by-step exploration of how premium coal-based activated carbon is made.

Step 1: Raw Material Selection – The Foundation of Quality

The quality of the raw material predetermines the quality of the finished activated carbon. The selection of the coal source is the first and most critical decision in the manufacturing chain, as it dictates the inherent physical properties of the final product. Not all Coal is created equal, and a reputable manufacturer invests significantly in sourcing and analysis at this initial stage.

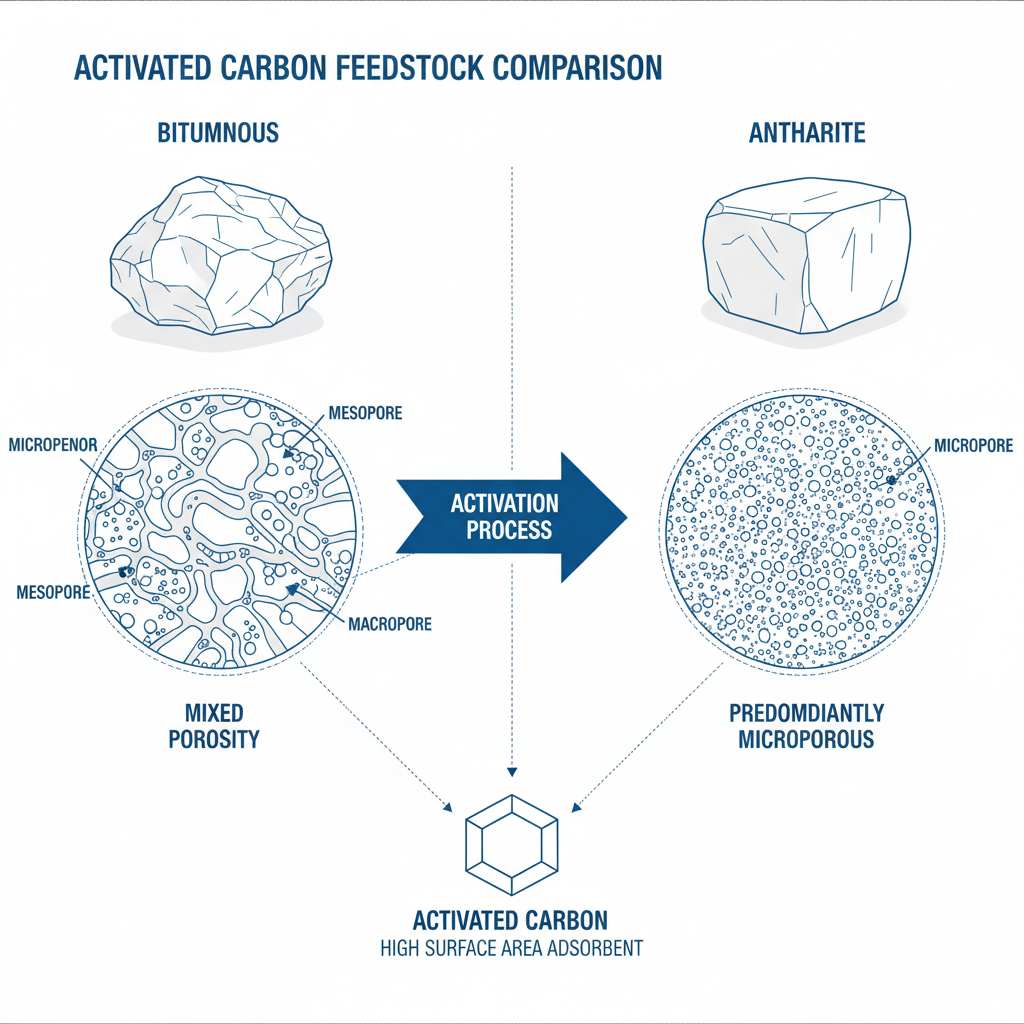

Bituminous vs. Anthracite: How Coal Type Impacts Final Pore Structure

The type of Coal used profoundly impacts the pore structure of the activated carbon. The two primary types used are bituminous and anthracite coal.

- Bituminous Coal: This is the most common raw material for activated carbon. Its relatively high volatile content and softer composition make it ideal for creating a well-developed pore structure during activation. Bituminous coal-based carbons typically exhibit various pore sizes, including micropores, mesopores, and macropores. This balanced porosity makes them exceptionally versatile for gas and liquid phase applications, effectively removing a broad spectrum of contaminants.

- Anthracite Coal: As a more complex, denser form of Coal with low volatile content, anthracite yields an activated carbon with superior hardness and abrasion resistance. The resulting product is primarily microporous, making it highly effective for adsorbing smaller organic molecules from gas streams and potable water. Its physical durability is a significant advantage in applications involving high-pressure drops or rigorous backwashing cycles.

The Critical Role of Purity: Analyzing Ash, Sulfur, and Moisture Content

Beyond the type of Coal, its purity is paramount. Non-carbonaceous impurities can negatively affect the activation process and contaminate the final product. Key parameters analyzed include:

- Содержание золы: This refers to the inorganic, incombustible material within the Coal. High ash content is undesirable as it does not contribute to the porous structure and can reduce the adsorptive capacity. Low-ash Coal is sought for producing high-grade activated carbon.

- Sulfur Content: Sulfur can lead to the emission of sulfur oxides during manufacturing and may result in a final product with undesirable acidic properties.

- Moisture Content: Excessive moisture requires additional energy to remove during processing and affects the accuracy of process calculations. Consistent, low-moisture Coal is essential for a stable manufacturing operation.

Step 2: Carbonization – Converting Coal into a Stable Carbon Char

Once a suitable coal source is selected, the next stage is carbonization, also known as pyrolysis. In this process, the raw Coal is heated to high temperatures (typically 600-900°C) in an oxygen-deficient, inert atmosphere (e.g., nitrogen or argon). The primary goal of carbonization is to drive off volatile compounds—such as tars, hydrogen, and methane—leaving behind a stable, carbon-rich material called char.

Pyrolysis Explained: Removing Volatiles in an Inert Atmosphere

By eliminating oxygen from the heating chamber, the process prevents the Coal from combusting. Instead, the intense heat breaks down the complex hydrocarbon structures within the Coal. This thermal decomposition removes a significant portion of the original mass, concentrating the carbon and creating an initial, rudimentary pore structure. The resulting char is a critical intermediate product, far more stable and porous than the raw Coal, but not yet “activated.”

Process Control: The Impact of Temperature and Time on Char Quality

The precise control of temperature and residence time during carbonization is vital. A slower heating rate and optimized temperature profile ensure that Volatiles are removed efficiently without damaging the carbon lattice. This meticulous control produces a high-quality char with maximum carbon yield and the ideal foundational structure for the subsequent activation stage.

Step 3: Activation – Engineering the Adsorptive Pore Network

Activation is the most crucial, value-adding step in the manufacturing process. It is where the carbon char is transformed into an adsorbent material with an astonishingly vast internal surface area—a single gram of activated carbon can have a surface area of over 1,000 square meters. This is achieved by selectively gasifying the carbon structure to create a complex network of microscopic pores.

Steam Activation: The Industry Standard for High-Purity Applications

The most common method for producing high-purity coal-based activated carbon is steam activation. The carbonized char is introduced into a furnace and exposed to superheated steam at high temperatures (typically 800-1100°C). The steam acts as an oxidizing agent, reacting with the carbon according to the endothermic reaction: C+H2O→CO+H2.

This reaction etches away at the internal carbon surfaces, developing and widening existing pores while creating countless new ones. This controlled erosion of the carbon lattice is what produces the material’s immense adsorptive capacity.

How Activation Conditions Define Surface Area and Porosity

The degree of activation—controlled by temperature, steam flow rate, and residence time—determines the product’s final characteristics.

- Lower Activation: Results in a predominantly microporous structure, ideal for adsorbing small molecules.

- Higher Activation: Widens the pores, creating more mesopores and macropores, which are better for adsorbing larger molecules and applications requiring faster diffusion rates.

- A skilled manufacturer can precisely manipulate these conditions to engineer activated carbons tailored for specific applications.

A Note on Chemical Activation: Niche Methods for Specialized Products

While less common for Coal, chemical activation is another method. It involves impregnating the raw material or char with a chemical agent, such as phosphoric acid or potassium hydroxide, followed by heating. This process typically occurs at lower temperatures than steam activation and can produce carbons with unique pore structures. However, steam-activated coal-based carbons are the preferred standard for most industrial water and air applications due to their purity and performance characteristics.

Step 4: Post-Activation Processing & Quality Assurance

The activated carbon produced in the furnace is not yet a finished product. It must undergo several post-processing steps to meet the end-user’s exact specifications. This stage is coupled with rigorous quality assurance to guarantee lot-to-lot consistency.

From Large Chunks to Precise Grades: Crushing, Sizing, and Screening

The raw activated carbon is first cooled and then sent for size reduction. Large crushers and mills break the material down, passing it through a series of screens to classify it into specific particle size distributions. This is how different grades, such as Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC), are produced. Standard GAC mesh sizes include 8×30 and 12×40; the numbers refer to the U.S. Sieve sizes. Precise particle size is critical for hydraulic performance in liquid phase systems and pressure drop in vapor phase systems.

Verifying Performance: Key QC Tests for Iodine Number, Hardness, and More

At every stage, but especially before packaging, samples are taken to a laboratory for quality control testing. These standardized tests, often based on ASTM methods, verify the product’s physical and adsorptive properties. Key tests include:

- Iodine Number: A measure of the micropore content and an indicator of the overall surface area. It is the most fundamental parameter for gauging activated carbon activity.

- Номер твердости/абразивности: Measures the carbon’s physical durability and resistance to degradation during backwashing and handling. A high hardness number is crucial for minimizing fines and extending the product’s service life.

- Apparent Density: Determines the mass of carbon that can be contained in a given volume, which is essential for sizing filters and adsorbers.

- Содержание золы: Confirms the purity of the final product.

Ensuring Reliability: Lot Traceability and the Certificate of Analysis (CoA)

Each batch, or lot, of activated carbon is assigned a unique identifier that allows for complete traceability back to the original raw material through the manufacturing process. A Certificate of Analysis (CoA) is generated for each lot, documenting the results of all QC tests. This document assures the end-user that the product they receive meets the required specifications.

How the Manufacturing Process Guarantees Performance in Your Application

Every stage of the coal-based activated carbon manufacturing process—from selecting the right Coal to the final QC test—is a critical control point. A manufacturer dedicated to excellence does not simply produce a commodity; they engineer a high-performance solution.

Linking Process Control to Adsorption Capacity and Product Lifespan

The meticulous control over pyrolysis and activation directly translates to a more consistent adsorption capacity. This means the carbon performs more effectively and for a longer duration, reducing the frequency of replacement or regeneration. Similarly, producing a hard, durable granule minimizes product loss during operation, leading to a lower total cost of ownership.

Why Partnering with a Technical Expert Matters More Than Price

When sourcing coal-based activated carbon, you are not just buying a product but investing in its manufacturer’s expertise and quality systems. A supplier with deep process knowledge can provide invaluable support, helping you select the precise grade for your application and ensuring you receive a consistent, reliable product every time. This partnership is the key to achieving optimal performance, compliance, and long-term value in your purification systems.

Suppose your application demands the highest standards of purity and performance. In that case, working with a supplier who can demonstrate mastery over the entire manufacturing process is critical.

Consult a Process Expert today to discuss your application requirements and identify the optimal activated carbon solution.