Why GAC Specifications are the Foundation of System Performance and ROI

Selecting the correct Granular Activated Carbon (GAC) is a critical engineering decision, not a commodity purchase. The performance, efficiency, and operational lifespan of any purification system—whether for municipal water, industrial process streams, or vapor phase applications—are directly dictated by the physical and chemical properties of the carbon media. A failure to understand these granular activated carbon specifications can lead to undersized systems, premature contaminant breakthrough, excessive operational costs, and non-compliance with regulatory standards.

This GAC technical guide is designed for the process engineer, the system designer, and the procurement manager. It moves beyond surface-level definitions to provide a deep, practical understanding of the key parameters found on any technical data sheet. By linking metrics like Iodine Number, CTC Activity, and mesh size to real-world outcomes, this guide provides the framework necessary to specify, evaluate, and select the optimal GAC for any application, ensuring technical performance and a clear return on investment.

Section 1: The Fundamentals of Granular Activated Carbon (GAC)

A firm grasp of the material’s foundational properties is essential to interpret advanced specifications correctly. This section covers the basic definition, manufacturing process, and scientific principles that govern GAC performance.

What is Granular Activated Carbon? A Definition

Granular Activated Carbon is a highly porous adsorbent material with a vast internal surface area. It is produced from carbonaceous raw materials, such as coconut shells, coal, or wood.1 Its primary function is to remove dissolved contaminants from liquids or gases through a process known as adsorption.

The Manufacturing Process: From Raw Material to Activated Carbon

The unique properties of GAC are developed through a multi-stage manufacturing process designed to create a vast network of internal pores.3

- Carbonization (Pyrolysis): The raw material, such as coconut shells, is heated to high temperatures (typically around $600-900^{\circ}C$) in an inert, low-oxygen atmosphere.3 This process, known as pyrolysis, removes volatile compounds and converts the raw material into a carbon-rich char.

- Activation: The char is then “activated” to dramatically increase its porosity and surface area. The most common method is steam activation, where the char is exposed to steam at very high temperatures ($900-1100^{\circ}C$).3 The steam reacts with the carbon, etching away at the internal structure to create a complex network of microscopic pores.3

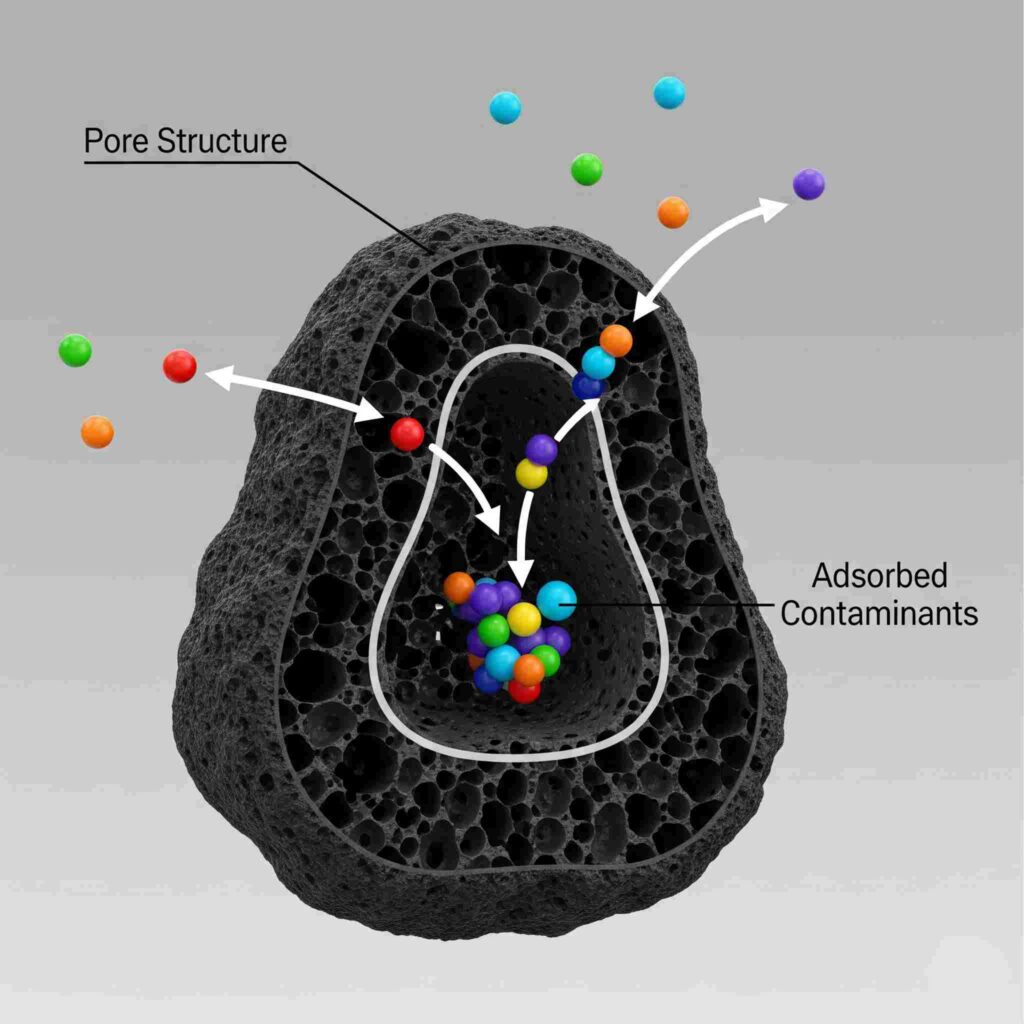

The Science of Adsorption: How GAC Captures Contaminants

GAC works through physical adsorption, a process where contaminant molecules are attracted to and held on the surface of the carbon by weak intermolecular forces known as van der Waals forces.1 The immense internal surface area of activated carbon—where a single gram can have a surface area of over $1,000 \text{ m}^{2}$—provides many sites for this adsorption.7 This process effectively traps and removes unwanted organic compounds, chlorine, odors, and other pollutants from the fluid stream passing through the GAC bed.9

Section 2: Decoding Key Performance Indicators: The Core GAC Specifications

This section provides a detailed analysis of the standard specifications on a GAC Technical Data Sheet (TDS). Understanding these metrics is essential for comparing products and matching a carbon to a specific application.

| Specification | What It Measures | Primary Application Relevance |

|---|---|---|

| Iodine Number | Microporosity: the ability to adsorb small molecules. | Liquid phase applications, particularly potable water treatment for removing taste, odor, and small organic compounds.10 |

| CTC Activity | Total pore volume; ability to adsorb volatile vapors. | Vapor phase applications include air purification, solvent recovery, and VOC removal.10 |

| Mesh Size | Particle size distribution of the granules. | Affects pressure drop, flow dynamics, and adsorption kinetics. Finer meshes offer more surface area but a higher pressure drop.8 |

| Hardness/Abrasion No. | Mechanical strength and resistance to attrition. | Determine durability during backwashing and handling, impacting media lifespan and operational costs.13 |

| Ash Content | Percentage of non-carbon, inorganic impurities. | A measure of purity. Low ash is critical for high-purity applications to prevent leaching of contaminants.7 |

| Bulk Density | Weight of carbon per unit of volume. | Essential for sizing treatment vessels and calculating the required mass of media for a given system volume.7 |

| Moisture Content | Percentage of water in the product as packaged. | Affects the net weight of active carbon being purchased and must be accounted for in system loading calculations.7 |

Iodine Number ($mg/g$): The Measure of Microporosity & Small Molecule Adsorption

The Iodine Number is one of the most fundamental parameters for GAC performance. It measures the micropore content of the activated carbon. It is determined by the amount of iodine adsorbed (in milligrams) by one gram of carbon. A higher Iodine Number indicates greater activation and a larger surface area for adsorbing small molecules.7 For liquid phase applications like drinking water treatment, a higher Iodine Number (typically $1,000 \text{ mg/g}$ or greater) is desirable as it correlates to a higher capacity for removing taste, odor, chlorine, and small dissolved organic compounds.7

Carbon Tetrachloride (CTC) Activity (%): Assessing Vapor Phase & VOC Capacity

CTC Activity is the primary indicator of a carbon’s capacity for vapor phase adsorption. It measures the loading of carbon tetrachloride vapor onto the GAC as a percentage of the carbon’s weight. This value is an excellent proxy for the total pore volume of the carbon and its ability to adsorb volatile organic compounds (VOCs) and other gaseous pollutants.10 A high CTC activity is a key performance metric for industrial air filtration, solvent recovery, or odor control applications.

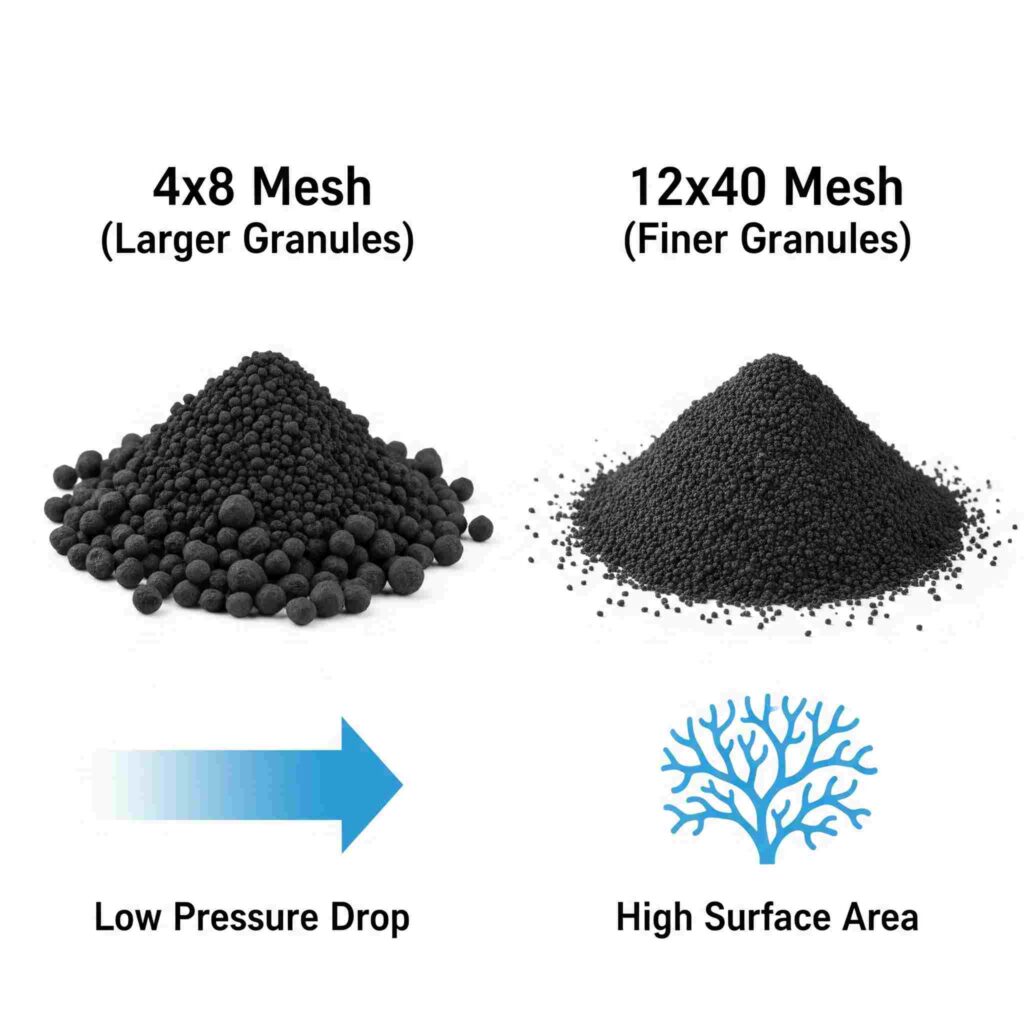

Mesh Size (e.g., 12×40, 4×8): Impact on Flow Rate, Pressure Drop, and Kinetics

Mesh size defines the particle size distribution of the granular carbon. A 12×40 mesh, for example, means most granules will pass through a U.S. Standard No. 12 sieve ($1.70 \text{ mm}$) but be retained by a No. 40 sieve ($0.42 \text{ mm}$).7 The choice of mesh size is a critical design trade-off:

- Smaller Particles (e.g., 12×40): Offer a larger external surface area, leading to faster adsorption kinetics. However, they create a more densely packed bed, resulting in a higher pressure drop across the system.12

- Larger Particles (e.g., 4×8): Result in a lower pressure drop, making them suitable for high flow rate applications. The trade-off is a smaller surface area and potentially slower adsorption rates.11

Hardness / Abrasion Number (%): Predicting Durability and Lifespan

The Hardness Number measures the GAC’s resistance to attrition and mechanical degradation. In many applications, GAC beds must be periodically backwashed to remove trapped particulates. This process causes the granules to collide and abrade. A high hardness number (e.g., $98\%$ or higher for coconut shell carbon) indicates that the media will experience minimal losses during handling, backwashing, and service, leading to a longer operational life and reduced makeup costs.13

Ash Content (%): A Critical Indicator of Purity and Potential Leachables

Ash is the non-carbon, inorganic residue that remains after the carbonaceous material is burned off. It consists of minerals inherent in the raw material. A low ash content is a key indicator of high purity.7 In sensitive applications, particularly in treating potable water or food-grade liquids, high ash content is undesirable as it can be a source of leachable inorganic contaminants.

Bulk Density ($lbs/ft^{3}$ or $g/cm^{3}$): Sizing Your System and Media Requirements

Bulk density is the mass of GAC that can be contained in a given volume, including the space between the granules. This parameter is not a direct performance measure but is critical for practical system design. It is used to calculate the total weight of carbon required to fill a filter vessel of a specific size and to estimate freight and handling costs.7

Moisture Content (%): Understanding Product as Packaged and Its Impact on Net Weight

This specification indicates the percentage of water in the GAC as it is packaged and shipped. A higher moisture content means a lower net weight of activated carbon per bag or unit. This value must be considered when calculating the total amount of product needed to achieve a specific dry-weight loading in a treatment system.7

Section 3: Advanced & Application-Specific Parameters

Beyond the core specifications, specific applications demand GAC with specialized properties. Understanding these advanced parameters is key to optimizing performance in high-value and niche industrial sectors.

Acid-Washed vs. Standard GAC: The Role of pH and Purity in Food, Beverage, and Pharmaceutical Applications

Standard GAC can have a slightly alkaline pH and may contain trace levels of acid-soluble inorganic impurities. For sensitive applications, an acid-washing step is performed post-activation. This process uses an acid (such as hydrochloric) to remove these impurities, resulting in a GAC with several key advantages17:

- Higher Purity: Significantly lower ash content and reduced levels of heavy metals.

- Neutral pH: The final product has a more balanced pH, preventing unwanted pH shifts in the treated liquid.17

- Enhanced Safety: Removing potential leachables makes it the preferred choice for the food and beverage, pharmaceutical, and high-purity water industries.17

Parameters for Gold Recovery: A Deep Dive into K-Value (Capacity) and R-Value (Rate)

In the precious metals industry, particularly in gold cyanidation circuits, performance is measured by two specific parameters18:

- K-Value: Represents the equilibrium adsorption capacity of the carbon for gold. A higher K-value means the carbon can hold more gold per unit weight.

- R-Value: Represents the rate of gold adsorption. A higher R-value indicates faster kinetics, meaning the gold is adsorbed more quickly from the solution.

The ideal carbon for gold recovery offers a balance of a high K-value, a high R-value, and exceptional Hardness to withstand the highly abrasive conditions of Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL) processes.18

Catalytic Carbon: Enhanced Performance for Chloramine and Hydrogen Sulfide ($H_{2}S$) Removal

Catalytic carbon is a specialized GAC that has been processed to alter its surface electronic structure, creating highly active catalytic sites. Unlike standard GAC, which removes contaminants primarily through physical adsorption, catalytic carbon actively promotes chemical reactions on its surface. This makes it exceptionally effective for removing challenging contaminants that are poorly adsorbed by standard carbon, such as16:

- Chloramines are used as municipal water disinfectants and broken down into harmless chlorides.

- Hydrogen Sulfide ($H_{2}S$): The cause of “rotten egg” odors is oxidized into non-odorous sulfate compounds.

Section 4: How to Select the Right GAC for Your Application

Synthesizing the technical specifications into a coherent selection strategy requires matching the carbon’s properties to the application’s demands.

The Golden Rule: Matching Pore Structure to Contaminant Size (Micropores, Mesopores, Macropores)

The effectiveness of GAC is fundamentally tied to its pore structure. The raw material dictates the final pore distribution:

- Micropores ($<2 \text{ nm}$): Ideal for adsorbing small molecules. Coconut shell-based GAC is predominantly microporous, making it the superior choice for removing small organic contaminants, chlorine, and disinfection byproducts from drinking water.14

- Mesopores ($2-50 \text{ nm}$): Better suited for adsorbing medium-sized molecules. Coal-based carbons typically have a mix of micro- and mesopores.23

- Macropores ($>50 \text{ nm}$): Act as transport pores and are effective for adsorbing giant molecules like color bodies. Wood-based carbons have a higher proportion of macro- and mesopores.21

Liquid Phase vs. Vapor Phase Applications: Which Specs Matter Most?

The priority of specifications changes depending on the medium being treated.

- For Liquid Phase (e.g., Water Treatment): Key parameters are Iodine Number (capacity for small organics), Hardness (durability for backwashing), Ash Content (purity), and Mesh Size (balancing kinetics and pressure drop).12

- For Vapor Phase (e.g., Air Purification): The most critical parameter is CTC Activity, which directly relates to the capacity for VOCs and gaseous pollutants. Hardness and Bulk Density are also crucial for system design and lifespan.11

A Practical Checklist for Specifying GAC

To ensure the selection of the correct GAC, an engineer should address the following questions:

- What is the application? (e.g., Potable Water, Industrial Wastewater, VOC Abatement)

- What are the target contaminants and their concentrations?

- What is the required effluent quality or removal efficiency?

- What is the medium? (Liquid or Vapor)

- What are the process conditions? (Flow Rate, Temperature, Pressure)

- Are there any system constraints? (e.g., Maximum allowable pressure drop)

- Is high purity required? (e.g., Food, Pharma – consider acid-washed)

- What is the expected service life and regeneration/replacement strategy?

Section 5: How to Read a GAC Technical Data Sheet (TDS)

A Technical Data Sheet (TDS) is the primary tool for evaluating and comparing GAC products. While formats vary slightly between manufacturers, they all contain the core specifications discussed in this guide.

Anatomy of a TDS: A Sample Walkthrough

When reviewing a TDS, look for these key sections and values:

- Product Name and Description: This will typically state the raw material (e.g., Coconut Shell GAC) and the intended application area.

- Physical Properties Table: This is the core of the TDS. It will list the specifications’ corresponding values and test methods (e.g., ASTM).

- Iodine Number: Look for a value in $mg/g$. For water treatment, a value of 1000 or higher is typical for high-quality carbon.7

- Деятельность КТК: Look for a percentage value. Values of $50-60\%$ or higher are common for vapor phase applications.10

- Mesh Size: This will be given as a range, such as 12×40 or 8×30.

- Hardness: Look for a high percentage, often $>98\%$ for coconut shell GAC.13

- Содержание золы: Look for a low percentage, typically $<4\%$ for standard GAC and even lower for acid-washed grades.8

- Operational Conditions: This section may provide recommended operating parameters, such as service flow rates (e.g., five $gpm/ft^{2}$) and backwash flow rates.7

You can make an informed, data-driven decision by systematically comparing these values against the requirements identified in your application checklist.

From Specification to Solution

Understanding granular activated carbon specifications is the first and most crucial step in designing an effective and economical purification system. Each parameter—from Iodine Number to Hardness—provides vital data that informs the selection process and predicts real-world performance. Engineers and managers can ensure their systems are optimized for efficiency, longevity, and compliance by moving beyond generic product descriptions and engaging with the technical data.

Key Takeaways: A Summary for the Busy Engineer

- Match the Pore Structure to the Contaminant: Coconut shell GAC (microporous) is ideal for small molecules in water; wood and coal carbons have larger pores for different targets.

- Prioritize Specs by Phase: Focus on Iodine Number and Hardness for the liquid phase. For the vapor phase, CTC Activity is paramount.

- Purity Matters: For sensitive applications like food, beverage, or pharmaceuticals, specify low-ash, acid-washed GAC to prevent contamination.

- Hardness Equals Longevity: A high hardness number translates directly to lower media loss and reduced operational costs over the system’s life.