Why These Four Specs Are Critical for Performance and Cost

When selecting activated carbon for an industrial or municipal application, it’s easy to focus on the upfront price per ton. However, its technical data sheet reveals the media’s actual value and long-term cost. Four key parameters—the “Big 4″—provide a comprehensive picture of an activated carbon’s performance, durability, and purity. Understanding these specifications is essential for any engineer, plant operator, or purchasing manager tasked with optimizing a purification process.

Looking beyond the initial purchase price to evaluate these metrics allows you to forecast operational efficiency, predict media lifespan, and calculate the total cost of ownership (TCO). This guide will demystify the Big Four activated carbon specs, explaining their measures and, more importantly, why they matter for your application.

You will learn:

- Iodine Value: The primary indicator of adsorption capacity for liquid-phase treatment.

- Hardness/Abrasion Number: The critical measure of durability and resistance to media loss.

- Ash Content: The key indicator of purity and potential for contamination.

- CTC Activity: The standard for measuring performance in vapor-phase applications.

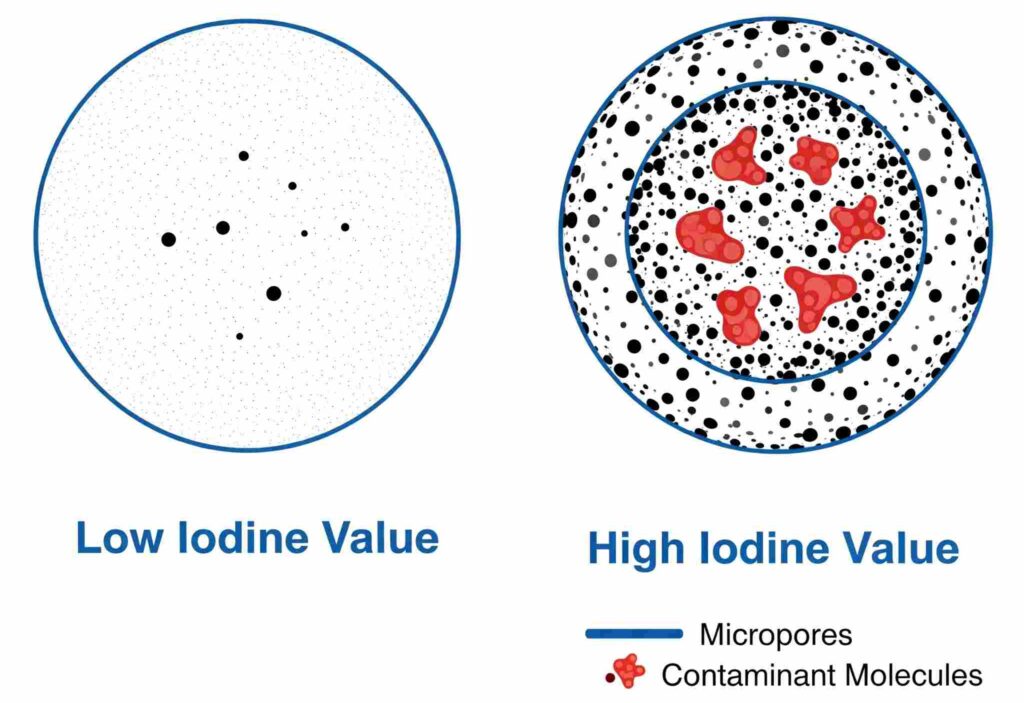

1. Iodine Value: The Ultimate Measure of Adsorption Capacity

What is Iodine Value?

The Iodine Value is the most fundamental parameter to characterize activated carbon performance, especially for liquid-phase applications like water treatment. It measures the carbon’s micropore content (pores up to 2 nanometers). It serves as an excellent indicator of its total internal surface area. The test, often performed according to standards like ASTM D4607, determines the milligrams of iodine that can be adsorbed by one gram of carbon (mg/g) from a solution.1

Why It Matters for Performance

A higher Iodine Value directly correlates to higher activation and greater surface area available for adsorption. This means the carbon has a greater capacity to remove small molecular weight organic contaminants from water. In municipal drinking water purification or industrial wastewater treatment, a high Iodine Value is critical for effectively removing taste and odor compounds, disinfection byproducts, and other dissolved organic pollutants.

Application Benchmarks

The required Iodine Value depends on the specific application and the necessary level of purity. While not a universal rule, the following ranges serve as a useful benchmark:

- General Water Treatment: An Iodine Value of 600-1100 mg/g is adequate for many standard municipal and industrial water treatment applications.

- High-Purity Water: Applications requiring the removal of trace organic contaminants, such as in the pharmaceutical or beverage industries, may specify a higher Iodine Value, often in the 900-1200 mg/g range.1

- Vapor Phase Applications: While less critical than for liquids, a higher Iodine Value indicates a well-activated carbon with good general capacity.

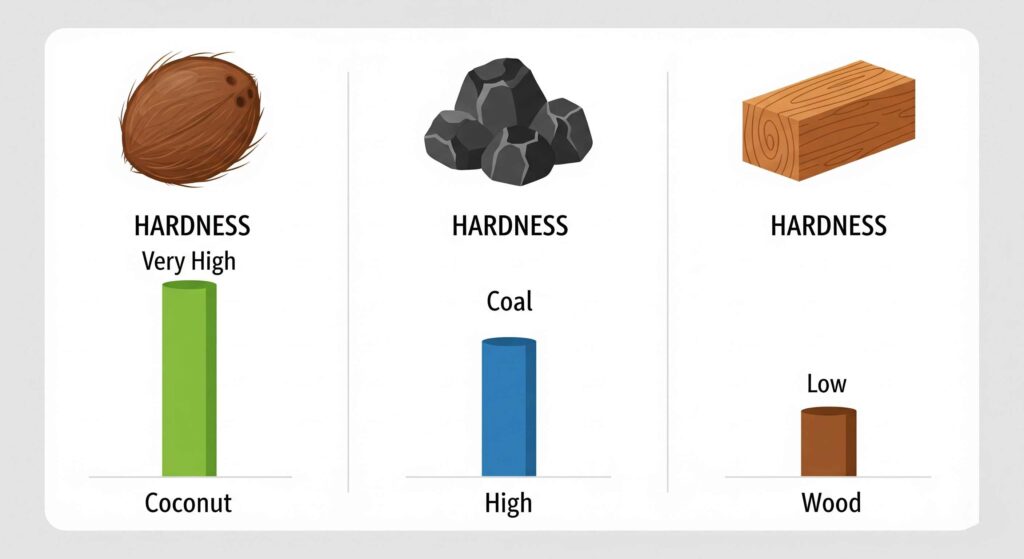

2. Hardness/Abrasion Number: The Key to Durability and Longevity

What is Hardness?

The Hardness or Abrasion Number measures the activated carbon’s physical integrity and ability to resist degradation from mechanical forces. The carbon particles are subjected to significant friction during shipping, loading, and particularly during the vigorous backwashing cycles required to clean a filter bed. This parameter quantifies how well the granules can withstand that stress without breaking down.

Why It Matters for TCO

Hardness is a critical economic parameter directly impacting the Total Cost of Ownership (TCO). A carbon with a low hardness number is friable, easily breaking apart and creating fine particles. This leads to several costly problems :

- Media Loss: Fines are washed away during backwashing, meaning you lose a portion of your expensive filter media with each cycle.

- Increased Pressure Drop: The accumulation of fines within the filter bed can restrict flow, leading to a higher pressure drop and increased energy costs for pumping.

- Frequent Replacement: A less durable carbon will need to be replaced more often, increasing material and labor costs.

Application Benchmarks

Hardness varies significantly based on the raw material used to produce the activated carbon. A higher number indicates greater durability.

- Coconut Shell Carbon: Highest resistance to abrasion (Hardness Number typically >90)

- Coal-Based Carbon: Very durable and suitable for most backwashing applications (Hardness Number ~70-95)

- Wood-Based Carbon: Generally softer and less resistant to attrition (Hardness Number ~85)

3. Ash Content: The Indicator of Purity and Efficiency

What is Ash Content?

Ash is the non-carbon, inorganic material that remains after the activated carbon has been completely combusted.6 It consists of minerals and metallic oxides inherent to the original raw material (e.g., coal, coconut shell, or wood). Ash content, expressed as a weight percentage, is the primary indicator of the purity of carbon.3

Why It Matters for Performance

A high ash content is undesirable as it negatively impacts performance in several ways:

- Reduces Adsorption Capacity: Ash is inert and does not contribute to adsorption. It occupies valuable pore volume that could otherwise be used to capture contaminants, thereby reducing the overall working capacity of the carbon.

- Lowers Regeneration Efficiency: Inorganic material can interfere with the thermal regeneration, making it less effective at restoring the carbon’s adsorptive properties.

- Potential for Leaching: Certain components of the ash, particularly water-soluble metal oxides like iron oxide (Fe2O3), can leach out of the carbon and into the treated water, potentially causing discoloration or other quality issues.

Application Benchmarks

A low-ash carbon is essential for applications where purity is paramount, such as in the food and beverage or pharmaceutical industries. Manufacturers can significantly reduce the ash content through a post-activation washing process.

- Standard Grade Carbon: May have an ash content ranging from 8-18%, depending on the raw material.

- Acid-Washed Carbon: This premium grade undergoes an acid washing step to remove soluble inorganic impurities, reducing the ash content to as low as 1-8%.

4. Carbon Tetrachloride (CTC) Activity: The Standard for Vapor-Phase Performance

What is CTC Activity?

While Iodine Value is the key metric for liquid-phase applications, Carbon Tetrachloride (CTC) Activity is the industry standard for evaluating gas and vapor-phase systems’ performance.14 The test, performed according to standards like ASTM D3467, measures the weight percentage of carbon tetrachloride vapor that a sample of activated carbon can adsorb.15 It directly indicates the carbon’s pore volume and capacity for capturing volatile organic compounds (VOCs) and other gaseous pollutants.

Why It Matters for Performance

A high CTC value correlates with better performance in any air or gas purification application.16 It indicates that the carbon has a well-developed pore structure capable of effectively trapping and holding organic vapors. This is the most essential specification to consider for systems designed for:

- Industrial air purification and VOC abatement

- Solvent recovery

- Odor control

- Biogas purification

Application Benchmarks

The required CTC value depends on the concentration and type of contaminants being removed. However, a higher value always indicates a higher-capacity carbon. For many general-purpose air treatment applications, a CTC value of 50% or more by weight is considered good, with high-quality carbons often exceeding 60-70%.

Making an Informed Decision with the “Big 4”

The technical data sheet for activated carbon provides a wealth of information that goes far beyond the initial price. By understanding the “Big 4” specifications, you can accurately assess a product’s potential performance, durability, and purity, allowing you to select the most effective and economical solution for your specific needs.

Quick-Reference Summary Table

Parameter: What It Measures, Its Important Application Focus

Iodine Value Micropore volume and relative surface area indicate capacity for adsorbing small molecules. Liquid-Phase (Water Treatment)

Hardness/Abrasion No. Resistance to physical breakdown ensures durability, minimizes media loss, and lowers TCO. Systems with Backwashing

Ash Content: The Amount of inorganic, non-carbon material. High ash reduces purity and adsorption capacity. High-Purity Applications

CTC Activity Adsorption capacity for vapor-phase contaminants Key indicator for VOC and odor removal performance Gas-Phase (Air Purification)

Prioritizing for Your Application

When evaluating a data sheet, prioritize the most relevant specs to your process. For liquid-phase systems like municipal water treatment, focus on achieving a high Iodine Value for maximum contaminant removal and a high Hardness Number to withstand backwashing and ensure a long service life. The CTC Activity is the most critical performance indicator for gas-phase systems like industrial VOC control. Hardness is also essential for durability in regenerative systems. By balancing these four key parameters, you can make a truly informed decision that optimizes performance and long-term cost.