The Versatile Workhorse of Industrial Purification

Few materials are as essential and versatile as coal-based activated carbon in industrial and municipal purification. From ensuring the safety of our drinking water to cleaning the air at industrial facilities, this powerful adsorbent is a silent, indispensable workhorse.1 Its unique ability to trap a vast range of contaminants is owed to a highly engineered internal structure, forged from humble raw materials into a high-performance purification medium.

For the process engineer, plant manager, or purchasing specialist, a deep understanding of this material is not just academic—it’s critical for optimizing processes, ensuring compliance, and managing costs. This guide is designed to be your definitive resource, providing the technical and practical knowledge needed to effectively select, implement, and manage coal-based activated carbon.

Here’s what you will learn:

- The foundational science behind what coal-based activated carbon is and how its structure dictates its function.

- A step-by-step look at the manufacturing process transforms raw coal into a powerful adsorbent.

- A clear, practical breakdown of how to read a technical data sheet and understand the key performance metrics that matter.

- The different physical forms of activated carbon and choosing the right one for your system.

- A survey of its most critical applications across water, air, and industrial processing.

- An objective, data-driven comparison against its main alternatives: coconut shell and wood-based carbons.

- Insight into the material’s full lifecycle, including regeneration and end-of-life considerations.

- Actionable guidance on safe handling and how to qualify a high-quality supplier.

1. What is Coal-Based Activated Carbon? A Foundational Overview

Defining the Adsorbent

Coal-based activated carbon is a highly porous filtration material produced by processing specific types of coal at high temperatures. It is not a simple filter that physically blocks particles; instead, it functions through adsorption, where contaminant molecules in a liquid or gas adhere to its vast internal surface area.4 This makes it exceptionally effective at removing dissolved organic compounds, chemicals, and taste and odor-causing substances that traditional filters cannot capture.

The Source Material: Bituminous vs. Anthracite vs. Lignite Coal

The performance characteristics of the final product are heavily influenced by the type of coal used as the raw material. The primary types include:

- Bituminous Coal: This is the most common raw material, prized for producing durable activated carbon with a balanced pore structure. It is highly versatile for both liquid and gas phase applications.

- Anthracite Coal: A more complex, more mature form of coal, anthracite yields an activated carbon with high mechanical strength and density, making it suitable for demanding applications.

- Lignite Coal: This is a softer, less mature coal. While it can produce activated carbon with a well-developed pore structure, it is generally less complicated than its bituminous or anthracite counterparts.

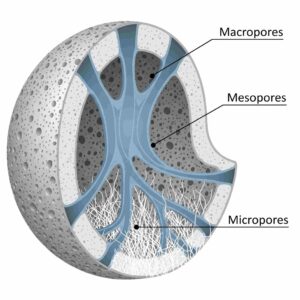

The Power of Pores

The true power of coal-based activated carbon lies in its intricate network of pores. The manufacturing process creates a unique and balanced distribution of different pore sizes, each playing a specific role in the adsorption process :

- Macropores (>50 nm): These are the most prominent pores, acting as the main highways into the carbon particle, allowing contaminant molecules to travel deep inside.

- Mesopores (2-50 nm): These intermediate-sized pores serve as transport arteries, branching off the macropores and leading to the smallest adsorption sites.

- Micropores (<2 nm): These are the smallest pores and comprise most of the internal surface area. This is where the bulk of adsorption occurs, as these pores are perfectly sized to trap and hold small- to medium-sized contaminant molecules.

This balanced pore structure gives coal-based activated carbon its signature versatility, effectively capturing a broader range of molecule sizes compared to more specialized carbons.

2. The Manufacturing Process: Forging a High-Performance Adsorbent

Retaining raw coal into a high-performance adsorbent is a carefully controlled, multi-stage process designed to create and refine the internal pore network.

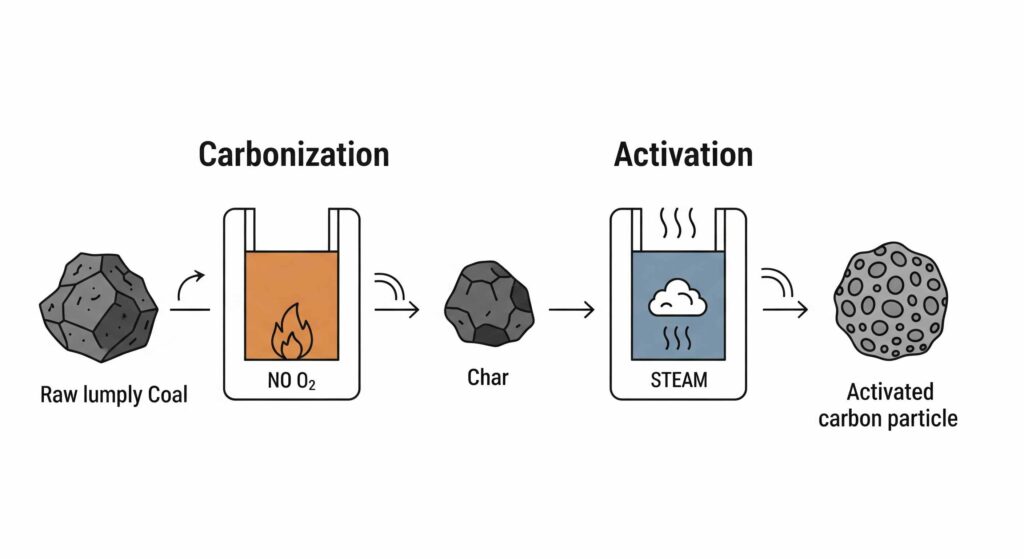

Step 1: Carbonization – Creating the Carbon Skeleton

The process begins with carbonization. Selected grades of coal are heated to extremely high temperatures (600–900°C) in an inert, oxygen-free environment. This intense heat drives off volatile compounds like water, methane, and hydrogen, leaving behind a carbon-rich material known as “char.” This char possesses a preliminary pore structure, but its surface area is not yet developed enough for effective adsorption

Step 2: Activation – Developing the Adsorptive Network

The char is then subjected to an activation process, which dramatically expands the pore network and increases the surface area. There are two primary methods:

Physical (Steam) Activation

This is the most common method for producing coal-based activated carbon. The carbonized char is exposed to superheated steam at even higher temperatures (up to 1200°C). The steam acts as a mild oxidizing agent, selectively gasifying the carbon atoms to etch away the internal surfaces. This process carves out and widens the existing pores and creates a vast network of new micropores, resulting in a highly adsorptive final product with a massive internal surface area.

Chemical Activation

The raw coal is first impregnated with a chemical agent, such as phosphoric acid or a strong base like sodium hydroxide. The mixture is then heated to a lower temperature (250–600°C). The chemical agent acts as a dehydrating and oxidizing agent, simultaneously breaking down the organic material and inhibiting tar formation, which could otherwise block pores. This method can tailor the pore structure for specific applications, often creating a carbon with more macropores, which is ideal for decolorizing liquids.

3. Decoding the Spec Sheet: Key Performance Parameters for Engineers and Buyers

Selecting the right activated carbon requires a clear understanding of its technical data sheet. These four key parameters provide critical insight into a product’s performance, durability, and purity.

Porosity and Surface Area (Iodine Value)

The Iodine Value is the most fundamental measure of activated carbon performance, particularly for liquid-phase applications. It indicates the micropore content (pores up to 2 nm) and is a proxy for the total surface area. A higher Iodine Value means more micropores and a greater capacity to adsorb small molecules. An Iodine Value between 900 and 1100 mg/g is typical for potable water treatment.

Mechanical Strength (Hardness/Abrasion Number)

This parameter measures the carbon’s ability to resist attrition and degradation from physical forces, such as those experienced during shipping, handling, and backwashing. A low hardness number means the carbon is friable and will break into fine particles, leading to material loss and increased pressure drop in a filter bed. Coal-based carbons typically have a high hardness (80-95%), ensuring durability and a longer operational life.

Purity (Ash Content)

Ash is the non-carbon, inorganic material that remains after the carbon is completely burned. It consists of minerals from the original raw coal. High ash content is undesirable because it reduces the overall carbon purity, occupies valuable pore space, and can lower the regeneration efficiency. Standard coal-based carbons may have an ash content of 8-18%, while acid-washed grades can have have this reduced to as low as 1-8% for high-purity applications.

Gas & Liquid Phase Capacity (CTC & Methylene Blue)

While Iodine Value is a general indicator, other tests measure capacity for specific applications:

- Carbon Tetrachloride (CTC) Activity: This is the standard measure for vapor-phase applications. It measures the ability of carbon to adsorb carbon tetrachloride vapor, which is reported as a percentage by weight. A higher CTC value indicates better performance for removing volatile organic compounds (VOCs) and other industrial gases.

- Methylene Blue Number: This test measures the carbon’s capacity to adsorb larger molecules from a solution, such as the dye methylene blue. It is a good indicator of the mesopore (2-5 nm) structure and is often used to gauge performance in decolorization applications.

| Parameter | What It Measures | Why It Matters | Typical Range (Coal-Based) |

|---|---|---|---|

| Iodine Value | Micropore content and relative surface area | Indicates capacity for adsorbing small molecules (e.g., organics in water) | 800 – 1100 mg/g 4 |

| Hardness/Abrasion No. (%) | Resistance to physical breakdown and dust formation | Ensures durability during backwashing and handling, minimizing material loss | 80 – 95% 4 |

| Ash Content (%) | Amount of inorganic, non-carbon material | High ash reduces purity and adsorption capacity; can be lowered by acid washing | 8 – 18% (Standard) 1 – 8% (Acid-Washed) 4 |

| CTC Activity | Adsorption capacity for vapor-phase contaminants | Key indicator for air purification and solvent recovery performance | 50 – 85% 4 |

4. Forms and Grades: Choosing the Right Carbon for Your System

Coal-based activated carbon is available in several physical forms, each engineered for specific equipment and process conditions.

Granular Activated Carbon (GAC)

GAC consists of irregular-shaped particles, typically ranging from 0.2 to 5 mm. It is the most common form used in fixed-bed adsorbers for liquid and vapor phase treatment.2 Its larger particle size allows for good hydraulic flow with a manageable pressure drop, making it the standard for municipal water filters and large-scale industrial systems.

Powdered Activated Carbon (PAC)

PAC is made of finely milled or crushed carbon particles, typically less than 0.1 mm. Its small particle size provides a very high external surface area, allowing extremely rapid adsorption kinetics.4 PAC is ideal for batch treatment processes where it is mixed directly with the liquid, allowed to adsorb contaminants, and then removed via filtration or settling. It is often used in municipal water plants for seasonal taste and odor control.

Pelletized (Extruded) Activated Carbon

This form is created by combining powdered activated carbon with a binder and extruding it into cylindrical pellets, typically ranging from 0.8 to 5 mm in diameter.4 The uniform shape of pellets provides excellent mechanical strength, low dust content, and a very low pressure drop. This makes pelletized carbon the preferred choice for gas-phase applications like solvent recovery and industrial air purification, where minimizing resistance to airflow is critical.

| Form | Key Characteristics | Primary Applications |

|---|---|---|

| Granular (GAC) | Irregular particles, good flow, reusable | Fixed-bed filters for municipal and industrial water treatment, vapor phase systems |

| Powdered (PAC) | Fine powder, rapid adsorption kinetics | Batch treatment in liquid phase, seasonal taste/odor control, emergency dosing |

| Pelletized (Extruded) | Uniform cylindrical shape, low pressure drop, high strength | Gas-phase systems, solvent recovery, industrial air purification, catalyst support |

5. A Versatile Workhorse: Key Applications Across Industries

The unique properties of coal-based activated carbon make it a critical component in various purification processes.

Municipal and Industrial Water Treatment

This is one of the largest applications for coal-based activated carbon. Potable water treatment removes natural organic matter, taste and odor compounds, and synthetic organic chemicals like pesticides.2 Industrial wastewater treatment effectively removes a broad spectrum of organic pollutants, helping facilities meet stringent discharge regulations.

Air and Gas Purification

In vapor-phase applications, coal-based activated carbon is essential for controlling air pollution. It is widely used to capture Volatile Organic Compounds (VOCs) from industrial processes, remove mercury from the flue gas of coal-fired power plants, and control odors at manufacturing and wastewater treatment facilities.1 Its high hardness and density make it robust enough to handle the conditions of these demanding systems.

Industrial Processing

Beyond environmental applications, coal-based activated carbon plays a key role in various industrial processes. These include:

- Decolorization: Removing color bodies from sugars, syrups, and other food and beverage products.

- Solvent Recovery: Adsorbing and recovering valuable solvents from process air streams in industries like printing and manufacturing, allowing them to be reused.

- Catalyst Support: Its large surface area and thermal stability make it an excellent carrier for precious metal catalysts used in the chemical industry.

6. Coal vs. The Alternatives: A Data-Driven Comparative Analysis

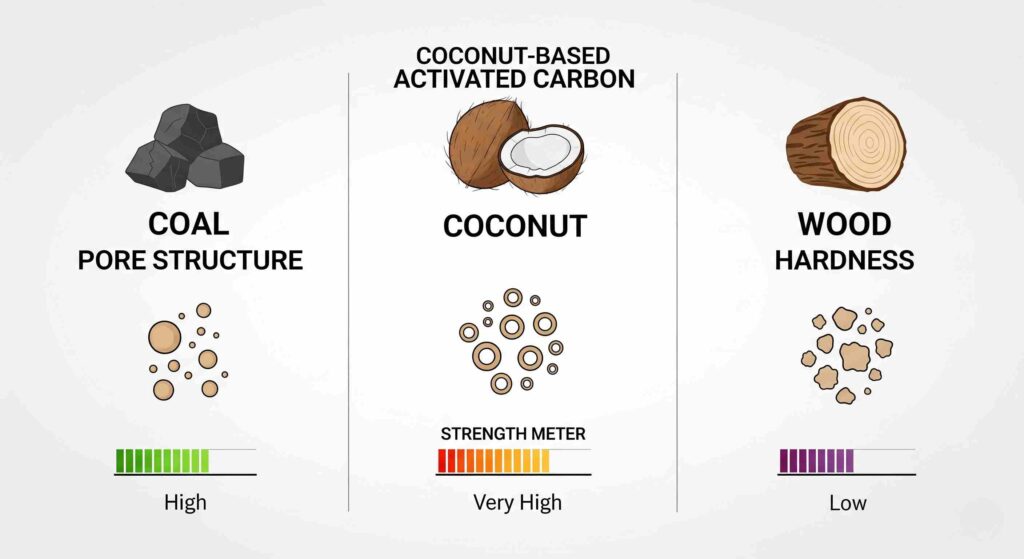

While coal-based activated carbon is a versatile workhorse, it is essential to understand how it compares to its main alternatives derived from coconut shells and wood. The choice of raw material fundamentally alters the carbon’s pore structure, hardness, and purity, making each type better suited for different applications.

Understanding the Contenders: Coconut Shell and Wood-Based Carbons

- Coconut Shell-Based Carbon: Produced from coconut husks, this carbon is renowned for its extremely high hardness and low ash content. Its pore structure is dominated by micropores, making it exceptionally good at adsorbing tiny organic molecules

- Wood-Based Carbon: Made from sawdust or wood chips, this carbon typically has a lower density and hardness. Its pore structure is characterized by a high volume of macropores and mesopores, which makes it an excellent choice for decolorizing liquids by removing large color bodies.

Head-to-Head Comparison: Performance, Properties, and Cost

The following table directly compares the key characteristics that differentiate these three primary types of activated carbon.

| Characteristic | Coal-Based (Bituminous) | Coconut Shell-Based | Wood-Based (Chemically Activated) |

|---|---|---|---|

| Primary Raw Material | Bituminous or Anthracite Coal | Coconut Shells (Renewable) | Sawdust/Wood (Renewable) |

| Dominant Pore Structure | Balanced mix of micropores and mesopores | Primarily micropores | Primarily mesopores and macropores |

| Typical Hardness/Abrasion No. (%) | High (90 – 95%) | Very High (>98%) | Low (~85%) |

| Typical Ash Content (%) | Medium to High (8 – 18%) | Very Low (<5%) | High (~15%) |

| Key Performance Advantage | Versatility for a wide range of molecule sizes in gas and liquid phases | Superior adsorption of small organic molecules (e.g., VOCs) | Excellent for decolorization and removal of large color bodies |

| Ideal Applications | Municipal water treatment, wastewater treatment, VOC abatement, solvent recovery. | Potable water filters (POU), gold recovery, air purification. | Food & beverage processing (sweetener decolorization), pharmaceutical purification |

7. The Lifecycle of Activated Carbon: Regeneration and Disposal

A significant advantage of granular activated carbon is its regenerative ability, crucial for the treatment process’s economic and environmental sustainability.

Why Regenerate? The Economic and Environmental Case

Over time, the pores of activated carbon become saturated with contaminants, and its adsorptive capacity diminishes. Instead of disposing of this “spent” carbon and purchasing virgin material, it can often be reactivated. Thermal regeneration destroys the adsorbed organic compounds and restores the carbon’s porous structure, allowing it to be reused.This process offers significant benefits:

- Cost Savings: Recycling the carbon virtually eliminates the high cost and long-term liability associated with disposal.

- Environmental Sustainability: Regeneration reduces the need for new raw materials and minimizes the amount of waste sent to landfills.

The Thermal Regeneration Process: A Step-by-Step Guide

Thermal regeneration is a precise, high-temperature process that essentially repeats the final stage of the original manufacturing process. It involves three key steps :

- Drying: The wet, spent carbon is first heated to approximately 105°C to evaporate residual water.

- Baking (Pyrolysis): The temperature is then raised between 105°C and 800°C in an oxygen-starved environment. This heat is high enough to break down and carbonize the adsorbed organic contaminants, driving them off as volatile gases without burning carbon.

- Activating: Finally, the carbon is exposed to an oxidizing atmosphere (typically steam) at temperatures above 800°C. This steam treatment burns off the carbonized residue left by the contaminants, clearing out the pores and restoring the original adsorptive capacity of the activated carbon.

End-of-Life Considerations

While regeneration is highly efficient, a small percentage of carbon (typically 5-10%) is lost as fines during each cycle. Eventually, carbon that can no longer be effectively regenerated must be disposed of. Depending on the contaminants it has adsorbed, spent carbon may need to be handled according to specific state and federal waste disposal regulations.

8. Practical Guidance: Safety, Handling, and Supplier Selection

Properly managing activated carbon involves more than just understanding its performance; it also requires adherence to safety protocols and a rigorous process for selecting suppliers.

Safety and Handling Best Practices

While activated carbon is non-hazardous, its physical properties require specific handling precautions, which are typically outlined in a Safety Data Sheet (SDS). Key safety points include:

- Dust Control: Fine carbon dust can be a respiratory irritant. Use in well-ventilated areas and wear appropriate respiratory protection if airborne concentrations are high.

- Oxygen Depletion: Wet activated carbon can adsorb oxygen from the air. This creates a severe hazard in confined spaces like storage tanks or vessels. Always test the oxygen level and follow confined space entry procedures before entering any vessel containing wet carbon.

- Ignition Sources: Carbon is difficult to ignite, but it can smolder. Keep it away from strong oxidizers, open flames, and welding operations. Use a hot work permit system when performing maintenance near carbon storage or handling areas.

- Spill Cleanup: Clean up spills in a manner that does not create airborne dust. Sweeping or vacuuming is preferred over using compressed air

How to Qualify a Supplier: A Buyer’s Checklist

Choosing a reliable supplier is critical to ensuring consistent product quality and performance. A purchasing manager or engineer should evaluate potential suppliers based on a comprehensive set of criteria:

- Quality Control and Consistency: Does the supplier have robust quality assurance processes? Ask for batch-wise test reports to verify that key parameters like Iodine Value and Hardness are consistent over time.

- Certifications and Compliance: For potable water applications, ensure the product is certified to NSF/ANSI 61 and meets AWWA standards. For industrial applications, look for ISO certification or adherence to ASTM test methods.

- Supply Chain Reliability: Can suppliers guarantee timely deliveries and manage inventory to prevent disruptions? It is often wise to diversify sourcing to avoid relying on a single manufacturer.

- Technical Support: Does the supplier offer technical expertise to help with product selection, system design, and troubleshooting? A valuable partner provides more than just a product; they provide solutions.

- Documentation: A qualified supplier should readily provide a Certificate of Analysis with each shipment and a comprehensive Safety Data Sheet (SDS).

Your Strategic Partner in Purification

Coal-based activated carbon is far more than a simple commodity; it is a highly engineered material fundamental to countless purification processes that protect public health and the environment. Its unique combination of a balanced pore structure, high mechanical hardness, and proven effectiveness makes it an exceptionally reliable and cost-effective choice for various demanding applications.

By understanding the journey from raw coal to finished adsorbent, decoding the critical parameters on a spec sheet, and appreciating its role in the broader context of industrial and municipal treatment, you are better equipped to make strategic decisions. Whether you are designing a new filtration system, optimizing an existing one, or managing the procurement of this essential material, the knowledge in this guide empowers you to select the right product, ensure its proper use, and maximize its value over its entire lifecycle.